Table of Contents

Understanding the Properties and Applications of 2 1/2 Sch40/Std ASTM A106 Hot Finished Seamless Steel Pipe

In the world of industrial materials, the 2 1/2″ Sch40/Std ASTM A106 Hot Finished Seamless Steel Pipe stands out as a crucial component for various applications across multiple sectors. Understanding its properties and applications is essential for engineers, manufacturers, and stakeholders involved in infrastructure projects, construction, and manufacturing processes.

The ASTM A106 specification sets the standard for seamless Carbon Steel pipe intended for high-temperature service. The “Sch40/Std” designation refers to the pipe’s schedule or thickness, with Sch40 indicating a standard wall thickness. This particular size of 2 1/2 inches combined with the Sch40 thickness makes it suitable for a range of demanding environments and operational conditions.

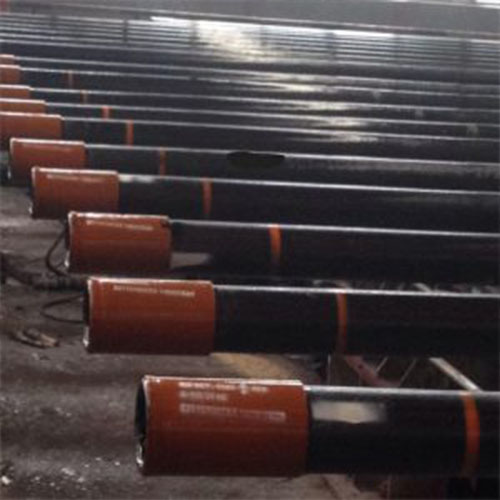

One of the primary attributes of ASTM A106 seamless Steel Pipes is their hot-finished manufacturing process. Hot finishing involves heating the steel billet to a temperature above its recrystallization point and then passing it through a series of rollers to achieve the desired dimensions and surface finish. This process ensures uniformity in composition and mechanical properties throughout the pipe’s length, resulting in enhanced strength and durability.

The seamless nature of ASTM A106 pipes eliminates the need for potentially weak weld seams, making them inherently more robust and reliable, particularly in high-pressure and high-temperature applications. This seamless construction also minimizes the risk of leaks and corrosion, extending the service life of the pipe and reducing maintenance requirements.

In addition to its superior mechanical properties, the 2 1/2″ Sch40/Std ASTM A106 Hot Finished Seamless Steel Pipe offers excellent thermal conductivity, making it suitable for conveying fluids and gases at elevated temperatures. This makes it a preferred choice for applications such as steam lines, boiler tubes, and Heat Exchangers in power generation plants, refineries, and chemical processing facilities.

Furthermore, the versatility of ASTM A106 seamless steel pipes extends beyond industrial settings. They find widespread use in commercial and residential construction projects for plumbing, HVAC Systems, and structural supports. Their durability, ease of installation, and compatibility with various joining methods make them a cost-effective and reliable solution for builders and contractors.

In the oil and gas industry, ASTM A106 seamless steel pipes play a critical role in upstream, midstream, and downstream operations. From drilling and production to transportation and refining, these pipes are integral to the extraction, processing, and distribution of hydrocarbons. Their ability to withstand harsh operating conditions, including corrosive environments and high-pressure flow, ensures the safe and efficient operation of oil and gas infrastructure worldwide.

Moreover, the 2 1/2″ Sch40/Std ASTM A106 Hot Finished Seamless Steel Pipe meets stringent quality standards and undergoes rigorous testing to ensure compliance with industry regulations and specifications. This quality assurance process includes dimensional inspection, mechanical testing, and non-destructive examination to verify the integrity and performance of the pipes.

In conclusion, the 2 1/2″ Sch40/Std ASTM A106 Hot Finished Seamless Steel Pipe is a versatile and reliable solution for a wide range of applications requiring high-strength, high-temperature, and corrosion-resistant piping. Its seamless construction, superior mechanical properties, and thermal conductivity make it indispensable in industries ranging from energy and construction to manufacturing and infrastructure development. Understanding its properties and applications is essential for maximizing its benefits and ensuring the success of engineering projects and industrial operations.