Table of Contents

Benefits of Using API 5CT-J55 and K55 Casing for Oil and Gas Field Applications

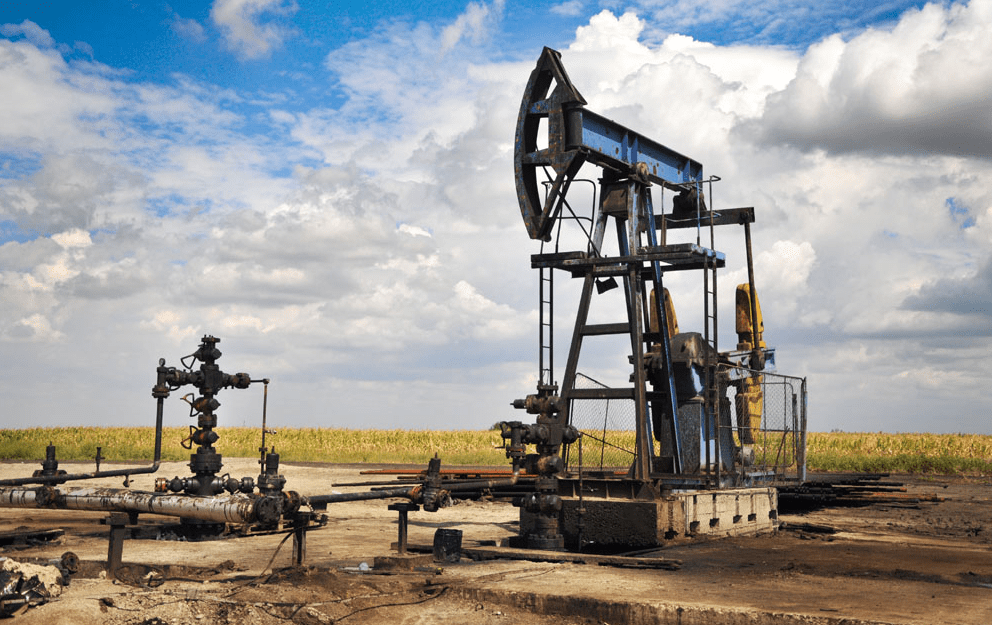

In the oil and gas industry, the choice of casing material is crucial to ensure the success and efficiency of drilling operations. API 5CT-J55 and K55 casing are two popular choices for oil and gas field applications due to their excellent properties and performance. These Carbon Steel seamless tubing options are designed to withstand the harsh conditions of drilling and extraction, making them ideal for use in various oil and gas field applications.

One of the key benefits of using API 5CT-J55 and K55 casing is their high strength and durability. These materials are specifically designed to withstand the extreme pressures and temperatures encountered during drilling operations. This ensures that the casing can effectively protect the wellbore and prevent any leaks or failures that could result in costly downtime and environmental damage.

Additionally, API 5CT-J55 and K55 casing are highly resistant to corrosion and erosion, making them ideal for use in corrosive environments such as offshore drilling rigs. This corrosion resistance helps to extend the lifespan of the casing and reduce the need for frequent maintenance and replacement, saving time and money in the long run.

Furthermore, API 5CT-J55 and K55 casing are designed to provide excellent sealing properties, ensuring that the wellbore remains secure and free from any contaminants. This helps to maintain the integrity of the well and prevent any leaks or spills that could have serious environmental consequences.

Another advantage of using API 5CT-J55 and K55 casing is their versatility and compatibility with a wide range of drilling equipment and tools. These materials can be easily welded and machined to fit specific requirements, making them suitable for use in various oil and gas field applications.

Moreover, API 5CT-J55 and K55 casing are cost-effective options for oil and gas companies looking to optimize their drilling operations. These materials offer a high level of performance and reliability at a competitive price point, making them a popular choice for both small and large-scale drilling projects.

In conclusion, API 5CT-J55 and K55 casing are excellent choices for oil and gas field applications due to their high strength, durability, corrosion resistance, sealing properties, versatility, and cost-effectiveness. These materials are specifically designed to withstand the harsh conditions of drilling operations and provide reliable protection for the wellbore. By choosing API 5CT-J55 and K55 casing, oil and gas companies can ensure the success and efficiency of their drilling operations while minimizing costs and environmental impact.

Comparison of Carbon Steel Seamless Tubing Nu/EU for Casing in Oil and Gas Fields

Casing is an essential component in the oil and gas industry, providing structural support and protection for the wellbore. API 5CT is a standard set by the American Petroleum Institute that specifies the technical requirements for casing and tubing used in oil and gas wells. Two common grades of casing material are J55 and K55, both of which are carbon steel seamless tubing.

J55 and K55 are similar in many ways, but there are some key differences that make them suitable for different applications in the oil and gas industry. J55 has a minimum yield strength of 55,000 psi, while K55 has a minimum yield strength of 55,000 psi as well. However, K55 has a higher tensile strength than J55, making it more suitable for applications where higher pressure and temperature conditions are expected.

In terms of chemical composition, J55 and K55 are very similar, with both grades containing carbon, manganese, and silicon as the main alloying elements. However, K55 also contains a small amount of chromium and Nickel, which gives it better corrosion resistance compared to J55. This makes K55 a better choice for wells that are exposed to corrosive environments.

When it comes to casing design, both J55 and K55 are available in two different types of connections: Nu and EU. Nu connections are non-upset, meaning that the ends of the casing are plain and do not have any additional threading. This type of connection is commonly used in shallow wells where the casing does not need to withstand high pressure or temperature conditions. On the other hand, EU connections are upset, meaning that the ends of the casing are threaded to provide a stronger connection. This type of connection is used in deeper wells where higher pressure and temperature conditions are expected.

In terms of cost, J55 is generally cheaper than K55 due to its lower tensile strength and corrosion resistance. However, the cost difference may not be significant enough to outweigh the benefits of using K55 in certain applications. It is important for operators to consider the specific requirements of their well before choosing between J55 and K55 casing.

Overall, both J55 and K55 are suitable choices for casing in oil and gas wells, but the decision between the two grades will ultimately depend on the specific requirements of the well. Operators should consider factors such as pressure, temperature, corrosion resistance, and cost when selecting the appropriate casing material. By choosing the right grade of casing, operators can ensure the integrity and longevity of their wells in the challenging Environment of the oil and gas industry.