Table of Contents

Benefits of Using Sodium Molybdate in Industrial Applications

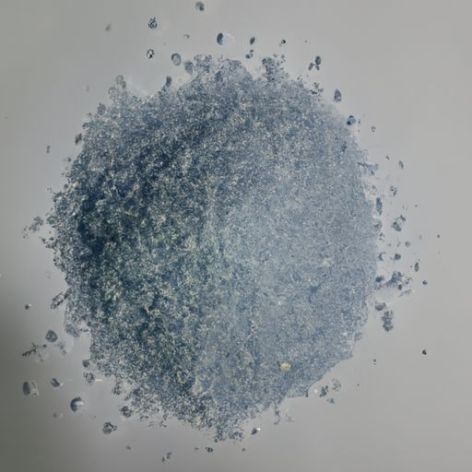

Sodium molybdate, also known as disodium molybdate, is a chemical compound with the formula Na2MoO4. It is a white, crystalline powder that is soluble in water and has a variety of industrial applications. This compound is commonly used as a corrosion inhibitor, a Fertilizer additive, and a Catalyst in various chemical reactions. In this article, we will explore the benefits of using sodium molybdate in industrial applications.

One of the primary benefits of using sodium molybdate is its effectiveness as a corrosion inhibitor. Corrosion is a major issue in many industries, as it can Lead to equipment failure, structural damage, and costly repairs. Sodium molybdate works by forming a protective film on metal surfaces, which helps to prevent corrosion and extend the lifespan of equipment. This compound is particularly effective in environments with high temperatures and acidic conditions, making it a valuable tool for industries such as oil and gas, chemical processing, and power generation.

In addition to its corrosion-inhibiting properties, sodium molybdate is also used as a fertilizer additive. Molybdenum is an essential micronutrient for plants, playing a key role in nitrogen metabolism and enzyme activation. By adding sodium molybdate to fertilizers, farmers can ensure that their crops receive an adequate supply of molybdenum, leading to improved growth, yield, and quality. This compound is particularly beneficial for leguminous crops such as Soybeans, Peas, and alfalfa, which have high molybdenum requirements.

Furthermore, sodium molybdate is a versatile catalyst in various chemical reactions. Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process. Sodium molybdate is used in the production of Chemicals such as dyes, pigments, and pharmaceuticals, where it helps to speed up reactions and improve product yields. This compound is also used in the petroleum industry to remove sulfur compounds from Crude Oil, leading to cleaner fuels and reduced environmental impact.

Overall, the benefits of using sodium molybdate in industrial applications are clear. From its corrosion-inhibiting properties to its role as a fertilizer additive and catalyst, this compound offers a wide range of advantages for various industries. By incorporating sodium molybdate into their processes, companies can improve equipment reliability, enhance crop productivity, and optimize chemical production. As technology continues to advance, the demand for sodium molybdate is expected to grow, making it an essential component in the industrial landscape.

In conclusion, sodium molybdate is a valuable chemical compound with numerous benefits for industrial applications. Whether it is used as a corrosion inhibitor, fertilizer additive, or catalyst, this compound plays a crucial role in enhancing efficiency, productivity, and sustainability across various industries. As companies strive to meet the challenges of a rapidly changing world, sodium molybdate will continue to be a key ingredient in their success.

How to Ensure Quality Control in Sodium Molybdate Production at the Factory

Quality control is a crucial aspect of any manufacturing process, especially when it comes to producing chemicals like sodium molybdate. This compound, also known as disodium molybdate, is commonly used in various industries, including Agriculture, electronics, and pharmaceuticals. Ensuring that the sodium molybdate produced at the factory meets the required standards is essential to guarantee its effectiveness and Safety in the end products.

One of the key factors in maintaining quality control in sodium molybdate production is to start with high-quality raw materials. The purity and composition of the starting materials can significantly impact the final product. Therefore, it is essential to source raw materials from reputable suppliers who can provide certificates of analysis to verify their quality. By using high-quality raw materials, the factory can ensure that the sodium molybdate produced meets the required specifications.

Once the raw materials are obtained, it is crucial to follow strict manufacturing processes to produce sodium molybdate. This includes carefully monitoring the temperature, pressure, and other parameters during the production process to ensure that the desired product is obtained. Any deviations from the standard operating procedures can result in impurities or variations in the final product, compromising its quality.

In addition to monitoring the production process, it is also essential to conduct regular quality control tests on the sodium molybdate produced at the factory. These tests can include analyzing the purity, composition, and physical properties of the compound to ensure that it meets the required specifications. By conducting these tests regularly, any deviations from the standard can be identified and corrected promptly, preventing the production of substandard sodium molybdate.

Another critical aspect of quality control in sodium molybdate production is to maintain a clean and controlled Environment in the factory. Contamination from dust, dirt, or other impurities can affect the quality of the final product. Therefore, it is essential to implement strict cleanliness protocols and regular maintenance of equipment to prevent contamination during the production process.

Furthermore, it is crucial to have a robust quality management system in place to oversee the entire production process. This system should include procedures for documenting and tracking the production process, conducting regular audits and inspections, and implementing corrective actions when deviations from the standard are identified. By having a comprehensive quality management system, the factory can ensure that the sodium molybdate produced meets the required quality standards consistently.

In conclusion, ensuring quality control in sodium molybdate production at the factory is essential to guarantee the effectiveness and safety of the compound in various applications. By starting with high-quality raw materials, following strict manufacturing processes, conducting regular quality control tests, maintaining a clean environment, and implementing a robust quality management system, the factory can produce high-quality sodium molybdate that meets the required specifications. By prioritizing quality control in every step of the production process, the factory can ensure the reliability and consistency of its sodium molybdate products, meeting the needs of its customers and maintaining its reputation in the industry.