Table of Contents

Benefits of Using a Polishing Machine for Capsules

Capsules are a popular form of medication delivery due to their ease of swallowing and precise dosing capabilities. However, before capsules can be packaged and distributed, they must undergo a polishing process to remove any dust, debris, or imperfections that may have accumulated during production. This is where a capsule polishing machine comes into play.

One of the main benefits of using a polishing machine for capsules is the ability to improve the overall appearance of the capsules. By removing any surface imperfections, such as dust or small particles, the capsules will have a clean and polished finish that is visually appealing to consumers. This can help to enhance the perceived quality of the product and instill confidence in the consumer that they are receiving a high-quality medication.

In addition to improving the appearance of the capsules, a polishing machine can also help to ensure the cleanliness and Safety of the product. Dust and debris can accumulate on the surface of capsules during production, handling, and storage, which can pose a risk to the consumer if ingested. By using a polishing machine to remove these contaminants, manufacturers can ensure that their capsules are safe for consumption and meet regulatory standards for cleanliness.

Another benefit of using a polishing machine for capsules is the ability to increase production efficiency. Manual polishing methods can be time-consuming and labor-intensive, requiring workers to inspect each capsule individually and remove any imperfections by hand. This can slow Down the production process and increase the risk of human error. By automating the polishing process with a machine, manufacturers can significantly increase their production output and reduce the likelihood of errors.

Furthermore, a polishing machine can help to extend the shelf life of capsules by removing any contaminants that could potentially cause degradation or spoilage. Dust and debris can attract moisture and bacteria, which can accelerate the breakdown of the capsule material and compromise the integrity of the medication inside. By keeping the capsules clean and free of contaminants, manufacturers can ensure that their products remain stable and effective for longer periods of time.

One of the key features of a capsule polishing machine is its ability to sort and separate capsules based on size, shape, and color. This can be particularly useful for manufacturers who produce multiple types of capsules and need to ensure that each batch is uniform and consistent in appearance. By using a polishing machine with sorting capabilities, manufacturers can streamline their production process and reduce the risk of mixing different types of capsules together.

Overall, the benefits of using a polishing machine for capsules are numerous and can have a significant impact on the quality, safety, and efficiency of the production process. By investing in a high-quality polishing machine, manufacturers can ensure that their capsules meet the highest standards of cleanliness and appearance, while also increasing production output and reducing the risk of errors. In today’s competitive pharmaceutical market, having a reliable and efficient polishing machine is essential for maintaining a competitive edge and meeting the demands of consumers and regulatory authorities alike.

How to Choose the Right Double Deduster Machinery Equipment for Capsule Polishing and Sorting

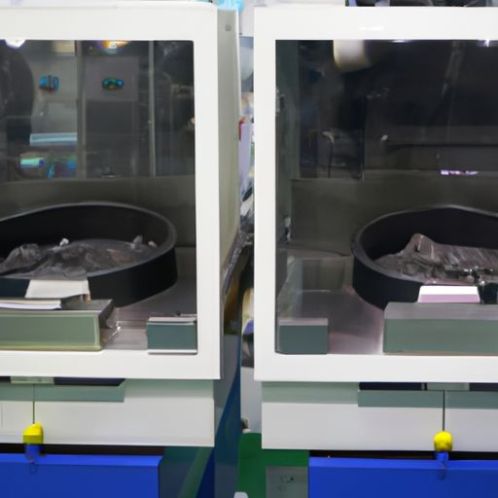

When it comes to capsule production, having the right equipment is crucial to ensure the quality and efficiency of the process. One key piece of machinery that plays a vital role in capsule production is the double deduster machine. This equipment is used for both polishing and sorting capsules, ensuring that they are free from dust, debris, and any other contaminants before being packaged and distributed.

There are several factors to consider when choosing the right double deduster machinery equipment for capsule polishing and sorting. One important factor to consider is the capacity of the machine. Depending on the size of your production facility and the volume of capsules you need to process, you will need to choose a machine that can handle the required capacity. It is important to choose a machine that can keep up with the demands of your Production Line to avoid any bottlenecks or delays.

Another important factor to consider is the efficiency and effectiveness of the machine. You want a machine that can effectively remove dust and debris from the capsules, ensuring that they meet the highest quality standards. Look for a machine that has a proven track record of performance and reliability in the industry. You may also want to consider the speed at which the machine operates, as faster processing times can help improve overall efficiency and productivity.

In addition to capacity and efficiency, it is also important to consider the versatility of the machine. Some double deduster machines are designed to handle a wide range of capsule sizes and types, while others may be more specialized. Depending on your specific needs and requirements, you may need a machine that can accommodate different capsule sizes and materials. It is important to choose a machine that is versatile enough to handle your current needs and any future changes or expansions to your production line.

In addition to capacity and efficiency, it is also important to consider the versatility of the machine. Some double deduster machines are designed to handle a wide range of capsule sizes and types, while others may be more specialized. Depending on your specific needs and requirements, you may need a machine that can accommodate different capsule sizes and materials. It is important to choose a machine that is versatile enough to handle your current needs and any future changes or expansions to your production line.

When choosing a double deduster machine for capsule polishing and sorting, it is also important to consider the maintenance and upkeep of the equipment. Look for a machine that is easy to clean and maintain, as regular maintenance is essential to ensure the longevity and performance of the machine. Consider the availability of spare parts and technical support, as well as any warranties or guarantees offered by the manufacturer.

One popular option for double deduster machinery equipment is the Capsule Polisher and Sorter Polishing Machine JMJ-3B. This specialized machine is designed specifically for capsule polishing and sorting, offering high efficiency and reliability. The JMJ-3B machine is capable of handling a wide range of capsule sizes and materials, making it a versatile option for capsule production facilities of all sizes.

In conclusion, choosing the right double deduster machinery equipment for capsule polishing and sorting is essential to ensure the quality and efficiency of your production process. Consider factors such as capacity, efficiency, versatility, and maintenance when selecting a machine for your facility. The Capsule Polisher and Sorter Polishing Machine JMJ-3B is a popular option that offers high performance and reliability for capsule production facilities. By carefully evaluating your needs and requirements, you can choose the right machine to meet your specific production needs and goals.