Table of Contents

Understanding API 5CT J55/K55 Casing and Tubing Pipe Specification

Understanding API 5CT J55/K55 Casing and Tubing Pipe Specification

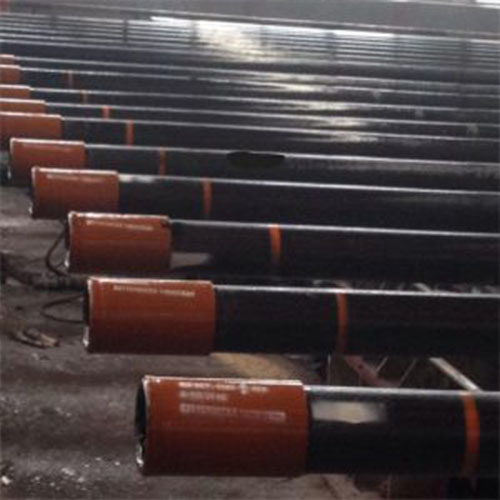

API 5CT J55/K55 casing and tubing pipes play a crucial role in the oil and gas industry. These pipes are designed to withstand the demanding conditions of oil and gas exploration and production. Understanding their specifications is essential for professionals working in this field.

Firstly, it’s important to grasp the significance of API 5CT. The American Petroleum Institute (API) sets standards for the design, manufacture, and testing of equipment used in the oil and gas industry. API 5CT is one such standard that covers casing and tubing used in wells for extracting oil and Natural Gas.

The designation “J55/K55” refers to the grades of steel used in the manufacture of these pipes. These grades are categorized as “group 1” and are among the most commonly used in oil and gas production. The primary difference between J55 and K55 lies in their chemical composition and mechanical properties.

J55 casing and tubing pipes are made from Carbon Steel and have a minimum yield strength of 55,000 psi. They are suitable for shallow to medium-depth wells and environments where the casing or tubing does not encounter corrosive elements. K55, on the other hand, has the same yield strength as J55 but has slightly different chemical composition requirements to improve its resistance to corrosion, especially in mildly sour environments.

When it comes to specifications, API 5CT outlines the requirements for dimensions, mechanical properties, chemical composition, testing methods, and marking of casing and tubing pipes. These specifications ensure that the pipes meet the necessary standards for use in oil and gas wells.

The dimensions of J55/K55 casing and tubing pipes are specified in terms of outside diameter (OD) and wall thickness. These dimensions are critical for ensuring proper fit and compatibility with other components in the wellbore, such as casing hangers and production tubing.

Mechanical properties such as yield strength, tensile strength, and elongation are vital Indicators of the performance of casing and tubing pipes under various operating conditions. API 5CT sets minimum requirements for these properties to ensure the integrity and reliability of the pipes during drilling, completion, and production operations.

Chemical composition requirements dictate the Levels of carbon, manganese, phosphorus, sulfur, and other elements in the steel used to manufacture J55/K55 casing and tubing pipes. These requirements are designed to optimize the balance between strength, ductility, and corrosion resistance.

Testing methods specified by API 5CT include hydrostatic testing, electromagnetic inspection, ultrasonic testing, and visual inspection. These tests are conducted to detect any defects or imperfections in the pipes that could compromise their performance or Safety in the wellbore.

Marking requirements ensure traceability and identification of J55/K55 casing and tubing pipes throughout their lifecycle. The markings typically include the manufacturer’s name or logo, pipe size, grade, heat number, and any applicable API monogram.

In conclusion, API 5CT J55/K55 casing and tubing pipes are essential components in oil and gas wells, and understanding their specifications is paramount for ensuring their proper selection, installation, and performance. By adhering to the requirements outlined in the API 5CT standard, operators can maintain the integrity and reliability of their wellbore equipment, ultimately contributing to the safe and efficient production of oil and natural gas.