Table of Contents

فوائد استخدام موليبدات الصوديوم في التطبيقات الصناعية

كيفية ضمان مراقبة الجودة في إنتاج موليبدات الصوديوم في المصنع

في الختام، فإن ضمان مراقبة الجودة في إنتاج موليبدات الصوديوم في المصنع أمر ضروري لضمان فعالية وسلامة المركب في مختلف التطبيقات. من خلال البدء بمواد خام عالية الجودة، واتباع عمليات التصنيع الصارمة، وإجراء اختبارات مراقبة الجودة المنتظمة، والحفاظ على بيئة نظيفة، وتنفيذ نظام قوي لإدارة الجودة، يمكن للمصنع إنتاج موليبدات الصوديوم عالي الجودة الذي يلبي المواصفات المطلوبة. من خلال إعطاء الأولوية لمراقبة الجودة في كل خطوة من عملية الإنتاج، يمكن للمصنع ضمان موثوقية واتساق منتجات موليبدات الصوديوم، وتلبية احتياجات عملائها والحفاظ على سمعتها في الصناعة.

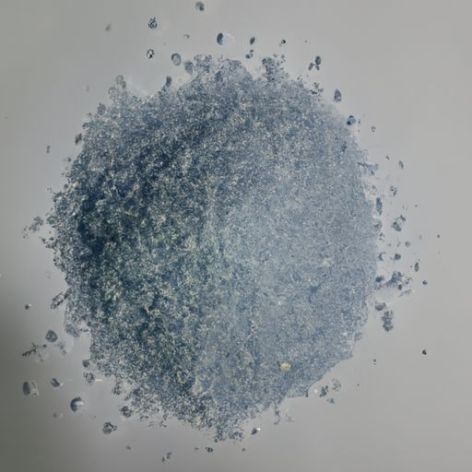

Quality control is a crucial aspect of any manufacturing process, especially when it comes to producing Chemicals like sodium molybdate. This compound, also known as disodium molybdate, is commonly used in various industries, including Agriculture, electronics, and pharmaceuticals. Ensuring that the sodium molybdate produced at the factory meets the required standards is essential to guarantee its effectiveness and Safety in the end products.

One of the key factors in maintaining quality control in sodium molybdate production is to start with high-quality raw materials. The purity and composition of the starting materials can significantly impact the final product. Therefore, it is essential to source raw materials from reputable suppliers who can provide certificates of analysis to verify their quality. By using high-quality raw materials, the factory can ensure that the sodium molybdate produced meets the required specifications.

Once the raw materials are obtained, it is crucial to follow strict manufacturing processes to produce sodium molybdate. This includes carefully monitoring the temperature, pressure, and other parameters during the production process to ensure that the desired product is obtained. Any deviations from the standard operating procedures can result in impurities or variations in the final product, compromising its quality.

In addition to monitoring the production process, it is also essential to conduct regular quality control tests on the sodium molybdate produced at the factory. These tests can include analyzing the purity, composition, and physical properties of the compound to ensure that it meets the required specifications. By conducting these tests regularly, any deviations from the standard can be identified and corrected promptly, preventing the production of substandard sodium molybdate.

Another critical aspect of quality control in sodium molybdate production is to maintain a clean and controlled Environment in the factory. Contamination from dust, dirt, or other impurities can affect the quality of the final product. Therefore, it is essential to implement strict cleanliness protocols and regular maintenance of equipment to prevent contamination during the production process.

Furthermore, it is crucial to have a robust quality management system in place to oversee the entire production process. This system should include procedures for documenting and tracking the production process, conducting regular audits and inspections, and implementing corrective actions when deviations from the standard are identified. By having a comprehensive quality management system, the factory can ensure that the sodium molybdate produced meets the required quality standards consistently.

In conclusion, ensuring quality control in sodium molybdate production at the factory is essential to guarantee the effectiveness and safety of the compound in various applications. By starting with high-quality raw materials, following strict manufacturing processes, conducting regular quality control tests, maintaining a clean environment, and implementing a robust quality management system, the factory can produce high-quality sodium molybdate that meets the required specifications. By prioritizing quality control in every step of the production process, the factory can ensure the reliability and consistency of its sodium molybdate products, meeting the needs of its customers and maintaining its reputation in the industry.