Table of Contents

Brushing Techniques for Mirror Finish on 2024 Aluminum Blanks

Brushing Techniques for Mirror Finish on 2024 Aluminum Blanks

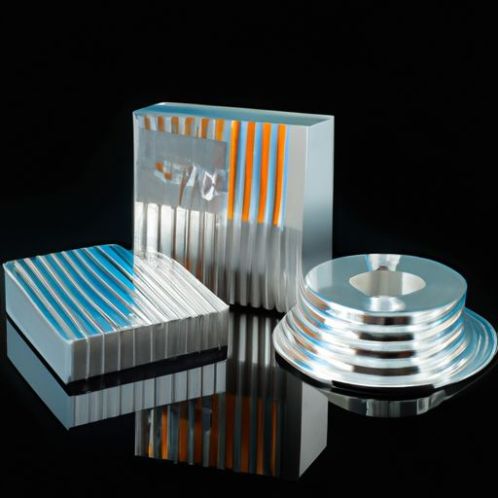

When it comes to achieving a mirror finish on 2024 aluminum blanks, brushing techniques play a crucial role in the process. The 2024 aluminum alloy is a high-strength material commonly used in aerospace applications due to its excellent strength-to-weight ratio. However, achieving a mirror finish on this material can be challenging due to its hardness and tendency to form a protective Oxide layer.

One of the most common techniques used to achieve a mirror finish on 2024 aluminum blanks is mechanical brushing. Mechanical brushing involves using abrasive materials such as sandpaper or wire brushes to remove surface imperfections and create a smooth, reflective surface. This technique is effective in removing scratches, dents, and other surface defects, but it requires skill and precision to avoid damaging the material.

Another technique that can be used to achieve a mirror finish on 2024 aluminum blanks is chemical brushing. Chemical brushing involves using acidic or alkaline solutions to etch the surface of the material and remove any impurities. This technique is less aggressive than mechanical brushing and can be used to achieve a uniform, mirror-like finish on the material.

In addition to mechanical and chemical brushing, electrochemical brushing can also be used to achieve a mirror finish on 2024 aluminum blanks. Electrochemical brushing involves using an electric current to remove surface imperfections and create a smooth, reflective surface. This technique is highly effective in achieving a mirror finish on aluminum blanks, but it requires specialized equipment and expertise to ensure consistent results.

Regardless of the brushing technique used, it is important to follow a systematic process to achieve a mirror finish on 2024 aluminum blanks. The first step in the process is to prepare the surface of the material by removing any surface contaminants and applying a protective coating to prevent oxidation. Once the surface is prepared, the brushing technique can be applied to remove surface imperfections and create a smooth, reflective surface.

During the brushing process, it is important to use the appropriate abrasive materials and techniques to avoid damaging the material. It is also important to maintain a consistent pressure and speed while brushing to achieve a uniform finish. After the brushing process is complete, the material should be cleaned and inspected to ensure that the desired mirror finish has been achieved.

In conclusion, achieving a mirror finish on 2024 aluminum blanks requires skill, precision, and the use of appropriate brushing techniques. Mechanical, chemical, and electrochemical brushing techniques can all be used to achieve a mirror finish on aluminum blanks, but each technique has its own advantages and limitations. By following a systematic process and using the appropriate techniques, it is possible to achieve a mirror finish on 2024 aluminum blanks that meets the highest quality standards.