Table of Contents

Understanding Casing Pipe: An Overview

Casing pipe plays a vital role in various industries, from oil and gas exploration to construction and water well drilling. Its importance lies in providing structural integrity and support to boreholes or wells, ensuring Safety, stability, and efficiency in operations. Understanding the significance, types, materials, and applications of casing pipe is essential for anyone involved in these industries.

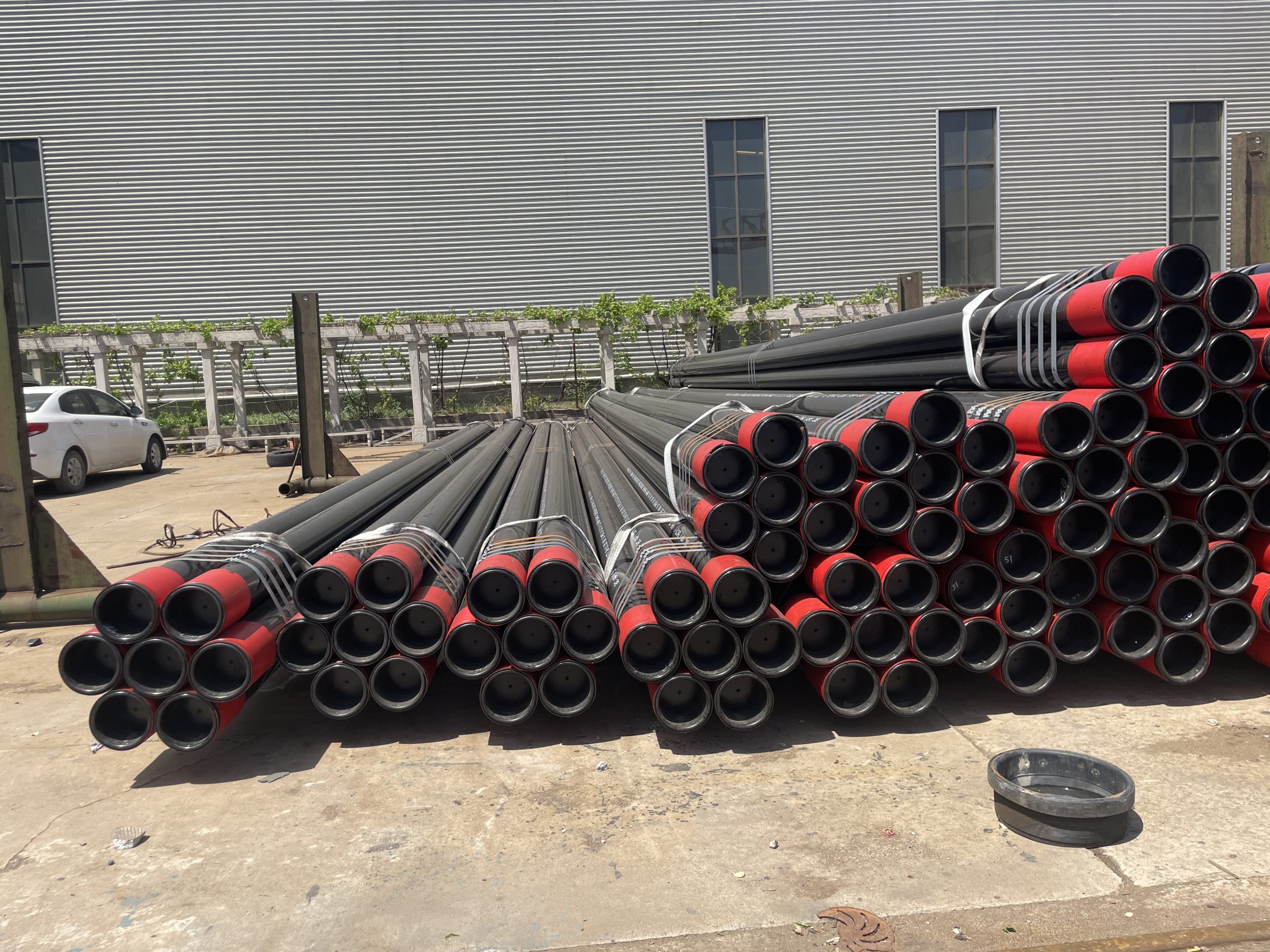

Casing pipe, also known simply as casing, is a cylindrical metal pipe installed in a drilled hole to prevent the hole from caving in and to facilitate drilling operations. It serves as a lining for the drilled hole, providing structural support and maintaining the integrity of the wellbore. Casing pipes are typically installed during the drilling process and are essential components in the construction of oil and gas wells, water wells, and geothermal wells.

One of the primary functions of casing pipe is to prevent the collapse of the borehole walls. During drilling, the surrounding geological formations exert pressure on the walls of the hole. Without proper support, these walls can collapse, compromising the integrity of the well and posing safety risks. Casing pipe reinforces the borehole, preventing collapse and ensuring the stability of the well.

Casing pipe also serves to isolate different geological formations and protect groundwater sources from contamination. By sealing off potentially hazardous formations and creating a barrier between different layers of rock and soil, casing pipe helps to safeguard the Environment and ensure the safety of surrounding communities.

There are several types of casing pipe, each designed for specific applications and operating conditions. The most common types include surface casing, intermediate casing, production casing, and conductor casing. Surface casing is the first casing installed in a well and is typically larger in diameter than other casings. It provides structural support near the surface and helps prevent groundwater contamination.

Intermediate casing is installed at intermediate depths to provide additional support and isolate specific formations. Production casing is the final casing installed in a well and is designed to withstand the pressure and conditions encountered during production operations. Conductor casing, also known as drive pipe, is used to support the weight of the drilling equipment and facilitate the drilling process.

Casing pipes are constructed from various materials, including steel, plastic, and composite materials. Steel casing pipes are the most common choice due to their strength, durability, and resistance to corrosion. They are available in various grades and specifications to suit different operating conditions and environments.

In addition to oil and gas wells, casing pipes are used in a wide range of other applications, including water well drilling, geothermal drilling, environmental remediation, and construction projects. In each of these applications, casing pipe plays a crucial role in ensuring the success and safety of the operation.

In conclusion, casing pipe is a critical component in various industries, providing structural support, stability, and environmental protection in drilling and construction operations. Understanding the importance, types, materials, and applications of casing pipe is essential for anyone involved in these industries to ensure safe and efficient operations.