Table of Contents

Benefits of Using Casing Tube in Drilling Operations

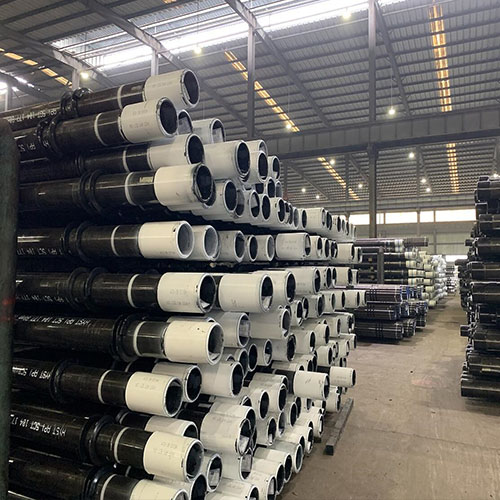

When it comes to drilling operations, having the right equipment is crucial for success. One essential component of any drilling operation is the casing tube. Casing tubes are used to support the walls of the borehole during drilling and are essential for maintaining the integrity of the hole. In this article, we will discuss the benefits of using casing tubes in drilling operations and why they are an essential tool for any drilling project.

One of the primary benefits of using casing tubes in drilling operations is their ability to prevent the collapse of the borehole walls. When drilling into the earth, the walls of the hole can become unstable and collapse without proper support. Casing tubes provide a sturdy barrier that helps to keep the walls of the borehole intact, preventing any potential collapse. This not only ensures the Safety of the drilling crew but also helps to maintain the integrity of the hole, allowing for a more efficient drilling process.

Another benefit of using casing tubes in drilling operations is their ability to prevent contamination of the surrounding Environment. When drilling into the earth, there is a risk of contaminating the surrounding soil and water with drilling fluids and other materials. Casing tubes help to contain these materials within the borehole, preventing them from seeping into the surrounding environment. This is essential for protecting the environment and ensuring that drilling operations are conducted in a safe and responsible manner.

In addition to preventing collapse and contamination, casing tubes also help to improve the efficiency of drilling operations. By providing a stable barrier around the borehole, casing tubes allow for more precise drilling and better control over the drilling process. This can help to reduce the risk of costly mistakes and delays, ultimately saving time and money for drilling companies.

Furthermore, casing tubes can also be used to protect sensitive formations during drilling operations. In some cases, drilling through certain formations can be challenging and may require additional support to prevent damage. Casing tubes can be used to provide this support, ensuring that the formation remains intact and undamaged during the drilling process. This is essential for preserving valuable resources and ensuring the success of the drilling project.

Overall, the benefits of using casing tubes in drilling operations are clear. From preventing collapse and contamination to improving efficiency and protecting sensitive formations, casing tubes play a crucial role in the success of any drilling project. For drilling companies looking to maximize their efficiency and minimize risks, investing in high-quality casing tubes is essential. By choosing a reliable and experienced casing tube manufacturer, drilling companies can ensure that they have the right equipment to support their drilling operations and achieve their goals.

How to Choose the Right Drill Bits Manufacturer in China

When it comes to choosing the right drill bits manufacturer in China, there are several factors that you need to consider. With so many options available in the market, it can be overwhelming to make a decision. However, by taking the time to research and evaluate your options, you can ensure that you are getting high-quality products that meet your specific needs.

One of the first things to consider when choosing a drill bits manufacturer in China is the quality of their products. It is important to look for a manufacturer that uses high-quality materials and advanced manufacturing techniques to produce durable and reliable drill bits. You can research the manufacturer’s reputation and read reviews from other customers to get an idea of the quality of their products.

Another important factor to consider is the range of products offered by the manufacturer. Different drilling projects require different types of drill bits, so it is important to choose a manufacturer that offers a wide variety of products to meet your specific needs. Whether you need casing tubes, drilling rods, or other types of drill bits, make sure that the manufacturer has the products you need in their inventory.

In addition to the quality and range of products, it is also important to consider the manufacturer’s customer service and support. A reputable manufacturer will have a team of knowledgeable and experienced professionals who can help you choose the right products for your drilling project and provide support throughout the purchasing process. Look for a manufacturer that offers excellent customer service and has a reputation for being responsive and helpful.

Price is another important factor to consider when choosing a drill bits manufacturer in China. While it is important to find high-quality products, you also want to make sure that you are getting a good value for your money. Compare prices from different manufacturers and consider factors such as shipping costs and delivery times to find the best deal for your budget.

When choosing a drill bits manufacturer in China, it is also important to consider their production capacity and Lead times. If you have a tight deadline for your drilling project, make sure that the manufacturer can meet your timeline and deliver the products on time. Look for a manufacturer that has a large production capacity and can handle large orders efficiently.

Overall, choosing the right drill bits manufacturer in China requires careful consideration of factors such as product quality, range of products, customer service, price, and production capacity. By taking the time to research and evaluate your options, you can find a manufacturer that meets your specific needs and provides high-quality products for your drilling projects.