Table of Contents

Benefits of Using Hot Dipped Threaded Process for Gas Pipes in China

China is known for its vast manufacturing capabilities, producing a wide range of products for both domestic and international markets. One of the key industries in China is the production of gas pipes, which are essential for Transporting Natural Gas from its source to various locations for consumption. In recent years, there has been a growing trend towards using hot dipped threaded processes for manufacturing gas pipes in China. This article will explore the benefits of using this process and why it has become increasingly popular in the industry.

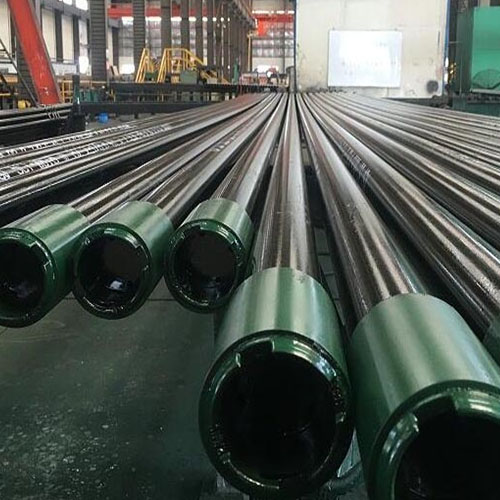

Hot dipped threaded processes involve coating Steel Pipes with a layer of Zinc to protect them from corrosion and rust. This process is commonly used in the production of gas pipes because it provides a durable and long-lasting finish that can withstand the harsh conditions of underground installation. The zinc coating also helps to prevent the formation of rust, which can weaken the pipes over time and Lead to leaks or other issues.

One of the main benefits of using hot dipped threaded processes for gas pipes in China is the increased durability and longevity of the pipes. The zinc coating provides a protective barrier that helps to prevent corrosion and rust, extending the lifespan of the pipes and reducing the need for frequent maintenance or replacement. This can result in cost savings for manufacturers and consumers alike, as well as a more reliable and efficient gas distribution system.

In addition to increased durability, hot dipped threaded processes also provide a more secure and reliable connection between pipes. The threaded process allows for a tight seal that helps to prevent leaks and ensure that the gas is transported safely and efficiently. This is especially important in the case of natural gas, which can be highly flammable and dangerous if not handled properly. By using hot dipped threaded processes, manufacturers can ensure that their gas pipes meet the highest Safety standards and provide a reliable means of transporting gas to its destination.

Another benefit of using hot dipped threaded processes for gas pipes in China is the versatility and flexibility it offers in terms of design and customization. Manufacturers can easily adjust the size, shape, and thickness of the pipes to meet the specific requirements of their customers, whether they are building a new gas distribution system or replacing existing pipes. This flexibility allows for greater innovation and creativity in the design and construction of gas pipes, leading to more efficient and effective systems overall.

Overall, the use of hot dipped threaded processes for gas pipes in China offers a wide range of benefits, including increased durability, reliability, and customization options. By choosing this process, manufacturers can ensure that their gas pipes are built to last and provide a safe and efficient means of transporting natural gas. As the demand for natural gas continues to grow, the use of hot dipped threaded processes is likely to become even more widespread in China and beyond.