Table of Contents

Benefits of Using a Door Cut CNC Metal Plasma Cutting Machine for Steel Carbon

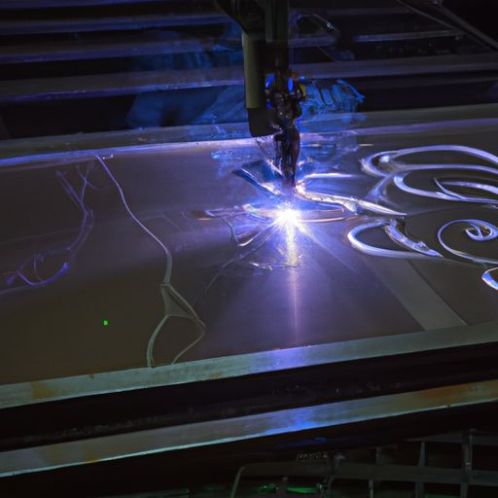

When it comes to cutting metal, precision and efficiency are key. Traditional methods of cutting metal can be time-consuming and labor-intensive, leading to inaccuracies and wasted materials. This is where a Door Cut CNC Metal Plasma Cutting Machine comes in. This cutting-edge technology offers a range of benefits for cutting steel carbon, making it a top choice for manufacturers and fabricators.

One of the main advantages of using a Door Cut CNC Metal Plasma Cutting Machine is its precision. The machine is equipped with a digital plasma system that allows for highly accurate cuts, ensuring that each piece of metal is cut to the exact specifications required. This level of precision is essential for industries that require tight tolerances and consistent quality in their metal products.

In addition to precision, a Door Cut CNC Metal Plasma Cutting Machine offers speed and efficiency. The machine is capable of cutting through thick metal sheets at a rapid pace, reducing production time and increasing output. This can Lead to significant cost savings for manufacturers, as they are able to produce more products in less time.

Furthermore, the digital plasma system used in a Door Cut CNC Metal Plasma Cutting Machine produces clean, smooth cuts that require minimal post-processing. This eliminates the need for additional finishing work, saving both time and money. The machine is also versatile, able to cut a wide range of metal thicknesses and shapes with ease.

Another benefit of using a Door Cut CNC Metal Plasma Cutting Machine is its ease of use. The machine is equipped with user-friendly Software that allows operators to input cutting parameters and control the cutting process with ease. This reduces the need for highly skilled operators, making it accessible to a wider range of users.

Additionally, a Door Cut CNC Metal Plasma Cutting Machine is a cost-effective solution for cutting metal. The machine is durable and reliable, requiring minimal maintenance and upkeep. This reduces downtime and ensures that the machine remains operational for years to come. The initial investment in a Door Cut CNC Metal Plasma Cutting Machine is quickly recouped through increased productivity and reduced waste.

Overall, a Door Cut CNC Metal Plasma Cutting Machine is a top-quality tool for cutting steel carbon. Its precision, speed, efficiency, and ease of use make it an essential piece of equipment for manufacturers and fabricators looking to streamline their production processes. With its clean cuts and cost-effective operation, this cutting-edge technology is a valuable asset for any metalworking operation.

Tips for Choosing Top Quality 1530 Metal Digital Plasma Cutting Machine

When it comes to metal fabrication, having the right tools is essential for achieving precise and efficient results. One such tool that has revolutionized the industry is the CNC metal digital plasma cutting machine. These machines use a high-velocity jet of ionized gas to cut through metal with incredible accuracy and speed. If you are in the market for a top-quality 1530 metal digital plasma cutting machine, there are a few key factors to consider to ensure you are making the best investment for your business.

First and foremost, it is important to consider the cutting capacity of the machine. The 1530 in the machine’s name refers to the size of the cutting bed, which is typically 1500mm by 3000mm. This size is ideal for cutting standard 4×8-foot sheets of metal, making it a versatile option for a wide range of projects. However, if you work with larger or smaller sheets of metal, you may need to consider a machine with a different cutting bed size.

In addition to cutting capacity, it is important to consider the power source of the machine. Most top-quality 1530 metal digital plasma cutting machines are powered by a high-frequency plasma generator, which provides the energy needed to cut through metal. It is important to choose a machine with a generator that is powerful enough to cut through the thickness of metal you typically work with. Additionally, some machines offer dual voltage capabilities, allowing you to switch between 110V and 220V power sources depending on your needs.

Another important factor to consider when choosing a top-quality 1530 metal digital plasma cutting machine is the cutting speed and accuracy. Look for a machine that offers high cutting speeds without sacrificing precision. This will allow you to complete projects quickly and efficiently while maintaining the quality of your cuts. Additionally, some machines offer advanced features such as automatic height control and torch height adjustment, which can further improve the accuracy of your cuts.

When it comes to durability and reliability, it is important to choose a machine from a reputable manufacturer. Look for a machine that is constructed from high-quality materials and features a sturdy frame that can withstand the rigors of daily use. Additionally, consider the warranty and customer support offered by the manufacturer, as this can provide peace of mind knowing that you will be supported in the event of any issues with your machine.

Finally, consider the overall cost of the machine, including any additional Accessories or software that may be required for your specific needs. While it is important to invest in a top-quality machine, it is also important to consider your budget and choose a machine that offers the best value for your money. Compare prices and features from different manufacturers to find the best option for your business.

In conclusion, choosing a top-quality 1530 metal digital plasma cutting machine is an important decision that can have a significant impact on the success of your metal fabrication business. Consider factors such as cutting capacity, power source, cutting speed and accuracy, durability and reliability, and overall cost when making your decision. By taking the time to research and compare different machines, you can find the perfect machine to meet your specific needs and help you achieve exceptional results in your metal fabrication projects.