Table of Contents

Benefits of Using En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes for Machine Applications

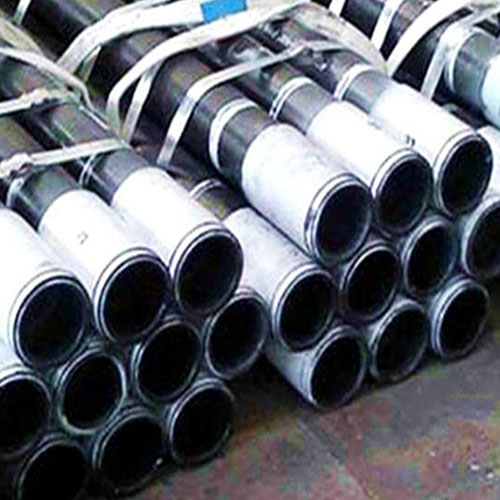

En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes are a popular choice for machine applications due to their numerous benefits. These pipes are known for their durability, corrosion resistance, and high strength, making them ideal for use in various industries. In this article, we will explore the advantages of using En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes for machine applications.

One of the key benefits of using En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes is their superior corrosion resistance. The hot-dip galvanizing process creates a protective layer of zinc on the surface of the steel, which helps prevent rust and corrosion. This makes these pipes ideal for use in environments where they may be exposed to moisture, Chemicals, or other corrosive elements.

In addition to their corrosion resistance, En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes are also highly durable. The galvanizing process adds an extra layer of protection to the steel, making it more resistant to wear and tear. This means that these pipes can withstand heavy use and harsh conditions, making them a reliable choice for machine applications.

Another advantage of using En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes is their high strength. The galvanizing process not only protects the steel from corrosion but also adds to its overall strength. This makes these pipes suitable for use in applications where they may be subjected to high pressure or heavy loads.

Furthermore, En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes are easy to install and maintain. The seamless design of these pipes ensures a tight, leak-free fit, reducing the risk of downtime and maintenance costs. Additionally, the galvanized coating helps extend the lifespan of the pipes, reducing the need for frequent replacements.

En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes are also environmentally friendly. The galvanizing process is a sustainable and energy-efficient method of protecting steel from corrosion, making these pipes a more eco-friendly option compared to other types of coatings. Additionally, the long lifespan of these pipes means that they require fewer resources for maintenance and replacement, further reducing their environmental impact.

In conclusion, En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes offer a range of benefits for machine applications. From their superior corrosion resistance and durability to their high strength and ease of installation, these pipes are a reliable and cost-effective choice for a variety of industries. Whether used in manufacturing, construction, or other applications, En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes are sure to deliver exceptional performance and longevity.

How to Properly Maintain En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes in Machine Operations

En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes are commonly used in machine operations due to their durability and resistance to corrosion. Proper maintenance of these pipes is essential to ensure their longevity and optimal performance. In this article, we will discuss some key maintenance tips to help you keep your En10255 pipes in top condition.

One of the most important aspects of maintaining En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes is regular inspection. Inspecting the pipes for any signs of damage, corrosion, or leaks is crucial in preventing potential issues that could Lead to costly repairs or replacements. It is recommended to inspect the pipes at least once a month to catch any problems early on.

In addition to regular inspections, it is also important to clean the pipes regularly to remove any dirt, debris, or other contaminants that could potentially cause damage. Using a mild detergent and a soft brush, gently scrub the surface of the pipes to remove any buildup. Avoid using harsh chemicals or abrasive materials, as this could damage the zinc coating and compromise the integrity of the pipes.

Another important aspect of maintaining En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes is ensuring proper storage and handling. When storing the pipes, make sure to keep them in a dry, well-ventilated area to prevent moisture buildup, which can lead to corrosion. Additionally, when handling the pipes, be careful not to drop or mishandle them, as this could cause dents or other damage that could compromise their structural integrity.

Regularly checking the connections and fittings of the pipes is also crucial in maintaining their performance. Make sure that all connections are tight and secure, and replace any damaged or worn fittings as needed. This will help prevent leaks and ensure that the pipes function properly.

In addition to these maintenance tips, it is also important to be mindful of the operating conditions in which the pipes are used. Extreme temperatures, high pressure, and corrosive environments can all have a negative impact on the performance of En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes. Make sure to monitor these conditions and take appropriate measures to protect the pipes from potential damage.

Overall, proper maintenance of En10255 Hot DIP Galvanized Zinc Coated Carbon Seamless Steel Pipes is essential in ensuring their longevity and optimal performance in machine operations. By following these maintenance tips and being proactive in caring for your pipes, you can help prevent costly repairs and replacements Down the line. Remember to inspect, clean, store, handle, and monitor the operating conditions of the pipes regularly to keep them in top condition.