Table of Contents

Benefits of Using a Five Axis Robot Arm in Plastic Injection Molding Industry

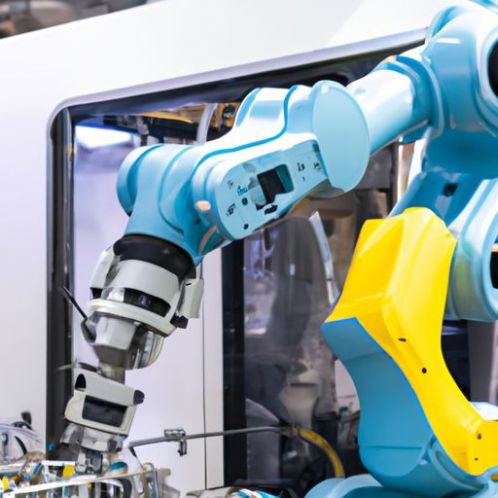

In the fast-paced world of plastic injection molding, efficiency and precision are key factors in ensuring the success of a manufacturing operation. One of the latest advancements in this industry is the use of five axis robot arms for take out in Injection Molding Machines ranging from 150T to 550T in size. These advanced robotic arms offer a wide range of benefits that can greatly improve the overall production process and quality of the final products.

One of the primary benefits of using a five axis robot arm in plastic injection molding is the increased speed and efficiency it brings to the Production Line. These robotic arms are capable of performing complex movements and tasks with a high degree of accuracy and speed, allowing for faster cycle times and increased productivity. This can result in significant cost savings for manufacturers, as more parts can be produced in a shorter amount of time.

In addition to speed and efficiency, five axis robot arms also offer improved precision and consistency in the production process. These robotic arms are programmed to perform the same movements and tasks with exact precision every time, eliminating the risk of human error and ensuring that each part is produced to the same high standard. This level of consistency can help manufacturers maintain a high level of quality control and produce parts that meet the strictest industry standards.

Another key benefit of using a five axis robot arm in plastic injection molding is the ability to handle a wide range of part sizes and shapes. These robotic arms are equipped with advanced Sensors and cameras that allow them to adapt to different part geometries and sizes, making them versatile enough to handle a variety of production requirements. This flexibility can be especially useful for manufacturers who produce a diverse range of parts and need a robotic solution that can easily switch between different tasks.

Furthermore, five axis robot arms are designed to be easy to program and operate, making them a user-friendly solution for manufacturers looking to streamline their production processes. These robotic arms can be programmed to perform a wide range of tasks, from simple pick-and-place operations to more complex assembly tasks, with minimal training required. This ease of use can help manufacturers reduce downtime and increase overall efficiency in their production operations.

Lastly, the use of a five axis robot arm in plastic injection molding can also improve workplace Safety by reducing the need for manual labor in potentially hazardous environments. These robotic arms are designed to work alongside human operators, taking on the more repetitive and physically demanding tasks while allowing workers to focus on more skilled and strategic aspects of the production process. This can help reduce the risk of workplace injuries and create a safer working Environment for employees.

In conclusion, the benefits of using a five axis robot arm in the plastic injection molding industry are clear. From increased speed and efficiency to improved precision and consistency, these advanced robotic arms offer a wide range of advantages that can help manufacturers stay competitive in today’s fast-paced manufacturing environment. By investing in this cutting-edge technology, manufacturers can streamline their production processes, improve quality control, and create a safer and more efficient workplace for their employees.

In conclusion, the benefits of using a five axis robot arm in the plastic injection molding industry are clear. From increased speed and efficiency to improved precision and consistency, these advanced robotic arms offer a wide range of advantages that can help manufacturers stay competitive in today’s fast-paced manufacturing environment. By investing in this cutting-edge technology, manufacturers can streamline their production processes, improve quality control, and create a safer and more efficient workplace for their employees.