Table of Contents

Exploring the Full Specifications of Alloy Steel Pipes: 5120, 5145, 4140, 4130, 4120, 1020, 1040, 5130, STKM11A

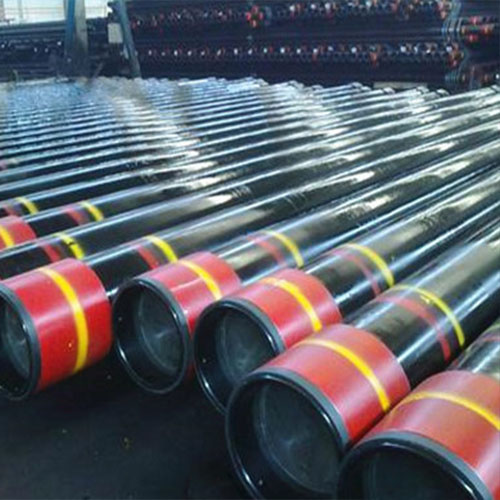

Exploring the full specifications of alloy Steel Pipes unveils a spectrum of choices, each with its unique properties and applications. Alloy steel pipes are engineered with varying compositions of elements such as chromium, Nickel, Molybdenum, and others to enhance their mechanical properties, corrosion resistance, and overall durability. In this comprehensive overview, we delve into the specifications and sizes of prominent alloy steel pipes including 5120, 5145, 4140, 4130, 4120, 1020, 1040, 5130, and STKM11A.

Alloy steel pipe 5120 is characterized by its moderate strength and excellent machinability. With a composition featuring chromium and molybdenum, it offers good hardenability, making it suitable for applications requiring high strength and wear resistance. Its seamless design ensures uniformity and reliability in critical industrial processes.

Moving on to alloy steel pipe 5145, we encounter a similar composition to 5120 with additional elements such as manganese and sulfur. This alloy exhibits improved hardenability and strength compared to 5120, rendering it suitable for applications demanding higher mechanical performance.

Alloy steel pipe 4140 is renowned for its exceptional strength, toughness, and fatigue resistance. Featuring chromium, molybdenum, and manganese, it offers superior hardenability and can withstand high-stress environments such as machinery components, automotive parts, and oil drilling equipment.

In contrast, alloy steel pipe 4130 boasts a composition emphasizing chromium and molybdenum, enhancing its corrosion resistance and weldability. Its versatility makes it a preferred choice for aerospace, automotive, and structural applications where both strength and formability are paramount.

Alloy steel pipe 4120, characterized by its chromium and molybdenum content, exhibits excellent hardenability and wear resistance. It finds applications in gears, Shafts, and other components requiring high strength and durability under demanding conditions.

Meanwhile, Carbon Steel pipes such as 1020 and 1040 offer distinct advantages in terms of cost-effectiveness and ease of fabrication. Alloying elements such as manganese and sulfur impart moderate strength and machinability, making them suitable for a wide range of industrial applications.

Alloy steel pipe 5130, featuring chromium and nickel, offers improved hardenability and corrosion resistance compared to its counterparts. Its seamless construction ensures uniformity and reliability in critical applications such as automotive components and machinery parts subjected to high temperatures and corrosive environments.

Finally, STKM11A carbon steel structural tubes exhibit excellent formability and weldability, making them ideal for structural applications in construction, infrastructure, and automotive industries. With a balanced composition of carbon, manganese, and sulfur, they offer reliable performance and durability in diverse operating conditions.

In conclusion, the full specifications and sizes of alloy steel pipes encompass a wide array of options catering to various industrial requirements. Whether it’s for high-stress applications demanding exceptional strength and toughness or for structural purposes requiring formability and weldability, alloy steel pipes offer unparalleled performance and reliability. Understanding the unique properties of each alloy is crucial in selecting the most suitable option for specific applications, ensuring optimal performance and longevity in critical industrial processes.