Table of Contents

Advantages of Using Glass Loading Machine Cutting Table JFDW-3624

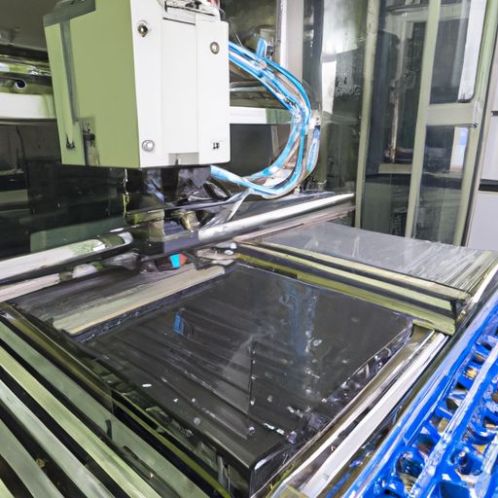

Glass loading machine cutting table JFDW-3624 is a versatile and efficient tool that offers a wide range of advantages for businesses in the glass industry. This machine combines automatic and manual features to streamline the glass cutting process and improve overall productivity. In this article, we will explore the various benefits of using the JFDW-3624 glass loading machine cutting table.

One of the key advantages of the JFDW-3624 is its ability to automate the glass loading process. This machine is equipped with a sophisticated loading system that can handle large sheets of glass with ease. By automating the loading process, businesses can significantly reduce the risk of breakage and improve overall efficiency. This feature is especially beneficial for businesses that deal with high volumes of glass cutting on a regular basis.

One of the key advantages of the JFDW-3624 is its ability to automate the glass loading process. This machine is equipped with a sophisticated loading system that can handle large sheets of glass with ease. By automating the loading process, businesses can significantly reduce the risk of breakage and improve overall efficiency. This feature is especially beneficial for businesses that deal with high volumes of glass cutting on a regular basis.

In addition to its automatic loading capabilities, the JFDW-3624 also offers manual cutting options for greater flexibility. This machine is equipped with a cutting table that can be adjusted to accommodate different sizes and shapes of glass. This allows businesses to customize their cutting process to meet the specific needs of each project. The manual cutting feature also gives operators greater control over the cutting process, ensuring precise and accurate results every time.

Another advantage of the JFDW-3624 is its high level of precision. This machine is designed to deliver precise cuts with minimal waste, helping businesses save time and money on materials. The cutting table is equipped with advanced technology that ensures clean and accurate cuts, even on complex shapes and designs. This level of precision is essential for businesses that require high-quality glass products for their projects.

The JFDW-3624 is also designed for ease of use and maintenance. This machine is equipped with user-friendly controls that make it easy for operators to program and operate. The cutting table is also designed for easy cleaning and maintenance, ensuring that the machine remains in top condition for years to come. This ease of use and maintenance helps businesses maximize their investment in the JFDW-3624 and ensures long-term reliability and performance.

Furthermore, the JFDW-3624 is a versatile machine that can handle a wide range of glass cutting tasks. Whether businesses need to cut simple shapes or intricate designs, this machine can deliver consistent and reliable results. The machine is also compatible with a variety of glass types, including tempered, laminated, and coated glass. This versatility makes the JFDW-3624 a valuable tool for businesses in the glass industry.

In conclusion, the glass loading machine cutting table JFDW-3624 offers a wide range of advantages for businesses in the glass industry. From its automatic loading capabilities to its high level of precision and versatility, this machine is designed to streamline the glass cutting process and improve overall productivity. By investing in the JFDW-3624, businesses can enhance their cutting capabilities, reduce waste, and deliver high-quality glass products for their projects.

Comparison between Automatic and Manual Hole Drilling Machines for Glass Loading Machine Cutting Table JFDW-3624

Glass loading machines are essential tools in the glass industry, used for cutting and drilling holes in glass sheets. One crucial component of these machines is the hole drilling machine, which can be operated either manually or automatically. In this article, we will compare the two types of hole drilling machines for the glass loading machine cutting table JFDW-3624.

Manual hole drilling machines require the operator to manually position the glass sheet and operate the drilling process. This type of machine is suitable for smaller-scale operations where precision is not as critical. On the other hand, automatic hole drilling machines are equipped with Sensors and computerized controls that allow for precise positioning and drilling of holes in glass sheets. These machines are ideal for larger-scale operations where accuracy and efficiency are paramount.

One of the main advantages of automatic hole drilling machines is their ability to drill multiple holes in a glass sheet with consistent precision. This is achieved through the use of computerized controls that ensure each hole is drilled at the exact location and depth specified. In contrast, manual hole drilling machines rely on the operator’s skill and experience, which can Lead to variations in hole placement and depth.

Another advantage of automatic hole drilling machines is their efficiency. These machines can drill holes in glass sheets at a much faster rate compared to manual machines. This is especially beneficial for high-volume production environments where time is of the essence. Additionally, automatic machines can be programmed to drill holes in a specific pattern or sequence, further increasing efficiency and productivity.

Despite the advantages of automatic hole drilling machines, manual machines still have their place in the glass industry. Manual machines are more cost-effective and easier to operate, making them suitable for smaller businesses or those with limited budgets. Additionally, manual machines offer greater flexibility in terms of hole size and shape, as the operator has more control over the drilling process.

In terms of Safety, automatic hole drilling machines are generally considered safer than manual machines. Automatic machines are equipped with safety features such as emergency stop Buttons and sensors that detect any obstructions in the drilling path. This reduces the risk of accidents and injuries in the workplace. Manual machines, on the other hand, rely on the operator’s vigilance and attention to detail to ensure safe operation.

In conclusion, both automatic and manual hole drilling machines have their own set of advantages and disadvantages. Automatic machines offer precision, efficiency, and safety, making them ideal for large-scale operations. Manual machines, on the other hand, are more cost-effective and flexible, making them suitable for smaller businesses. Ultimately, the choice between automatic and manual machines will depend on the specific needs and requirements of the glass loading machine cutting table JFDW-3624.