Table of Contents

Maintenance Tips for Extending the Lifespan of Hot DIP Galvanized Steel Pan Feeding Pipes in Poultry Farming Operations

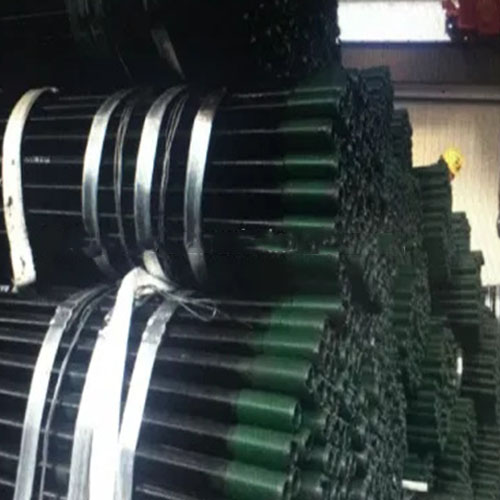

Hot DIP galvanized steel pan feeding pipes are a crucial component in poultry farming operations, particularly in broiler production. These pipes play a vital role in delivering feed to the birds efficiently and effectively. However, like any other equipment, they require regular maintenance to ensure their longevity and optimal performance.

One of the key maintenance tips for extending the lifespan of hot DIP galvanized steel pan feeding pipes is to regularly inspect them for any signs of wear and tear. This includes checking for rust, corrosion, or any other damage that may compromise the integrity of the pipes. It is important to address any issues promptly to prevent further deterioration and potential failure of the pipes.

In addition to visual inspections, it is also recommended to clean the pan feeding pipes regularly to remove any dirt, debris, or feed residues that may accumulate inside. This not only helps to maintain the hygiene of the pipes but also prevents blockages that can impede the flow of feed to the birds. Cleaning can be done using a mild detergent and water, followed by thorough rinsing to ensure that no residue is left behind.

Another important maintenance tip is to ensure that the pan feeding pipes are properly installed and secured. Loose or improperly fitted pipes can Lead to leaks, spills, and other issues that can affect the efficiency of the feeding system. It is essential to check the connections, joints, and supports regularly to ensure that everything is in place and functioning correctly.

Furthermore, it is advisable to lubricate the moving parts of the pan feeding pipes, such as the hinges and mechanisms, to reduce friction and wear. This can help to prolong the lifespan of the pipes and ensure smooth operation. Using a suitable lubricant, such as silicone or graphite-based lubricants, can help to maintain the functionality of the pipes and prevent premature failure.

Regularly inspecting and maintaining the hot DIP galvanized steel pan feeding pipes can help to prevent costly repairs or replacements Down the line. By taking proactive measures to care for the pipes, poultry farmers can ensure that their feeding systems operate efficiently and effectively, leading to improved productivity and profitability.

In conclusion, hot DIP galvanized steel pan feeding pipes are an essential component in poultry farming operations, particularly in broiler production. By following these maintenance tips, farmers can extend the lifespan of their pipes and ensure the smooth operation of their feeding systems. Regular inspections, cleaning, proper installation, lubrication, and proactive maintenance are key to maximizing the longevity and performance of the pan feeding pipes. By investing time and effort in caring for these essential components, poultry farmers can optimize their operations and achieve success in their broiler production endeavors.