Table of Contents

Differences Between J55, K55, N80, L80, P110, and S135 Casing Tubing Materials

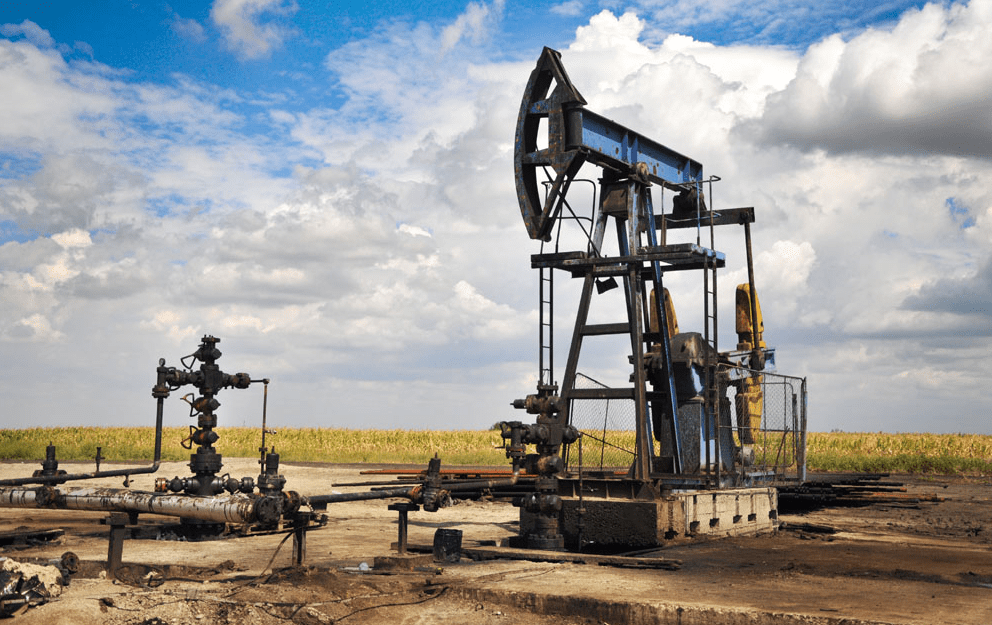

When it comes to choosing the right casing tubing material for your oil and gas drilling operations, there are several options available in the market. Some of the most commonly used materials include J55, K55, N80, L80, P110, and S135. Each of these materials has its own unique properties and characteristics that make them suitable for different applications. In this article, we will explore the differences between these materials to help you make an informed decision when selecting the right casing tubing for your project.

J55 is a low Carbon Steel grade that is commonly used in shallow wells where the pressure is not too high. It has a minimum yield strength of 55,000 psi and is known for its good weldability and formability. K55, on the other hand, is very similar to J55 in terms of its chemical composition and mechanical properties. The main difference between the two is that K55 has a higher tensile strength, making it more suitable for wells with higher pressure Levels.

N80 is a higher grade casing tubing material that is commonly used in medium depth wells. It has a minimum yield strength of 80,000 psi and is known for its excellent resistance to corrosion and cracking. N80 is also more expensive than J55 and K55, but it offers better performance in harsh drilling environments.

L80 is another high-grade casing tubing material that is commonly used in deep wells where high pressure and temperature conditions are present. It has a minimum yield strength of 80,000 psi and is known for its excellent mechanical properties and resistance to corrosion. L80 is also more expensive than N80, but it offers superior performance in challenging drilling conditions.

P110 is a high-strength casing tubing material that is commonly used in deep wells with high pressure levels. It has a minimum yield strength of 110,000 psi and is known for its excellent resistance to corrosion and cracking. P110 is more expensive than L80, but it offers superior performance in extreme drilling conditions.

S135 is the highest grade casing tubing material available in the market. It has a minimum yield strength of 135,000 psi and is known for its exceptional mechanical properties and resistance to corrosion. S135 is the most expensive casing tubing material on the market, but it offers unmatched performance in the most challenging drilling environments.

In conclusion, when selecting the right casing tubing material for your oil and gas drilling operations, it is important to consider the specific requirements of your project, such as the depth of the well, the pressure levels, and the temperature conditions. Each of the materials discussed in this article has its own unique properties and characteristics that make them suitable for different applications. By understanding the differences between J55, K55, N80, L80, P110, and S135 casing tubing materials, you can make an informed decision and ensure the success of your drilling operations.