Table of Contents

Benefits of Using a 10W Laser Engraver Machine for Leather Engraving

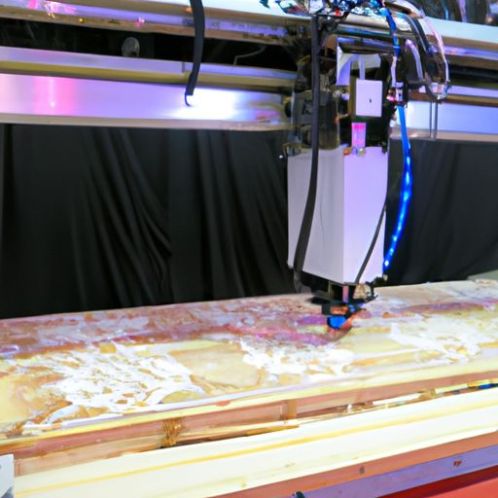

Laser engraving has become a popular method for adding intricate designs and patterns to various materials, including leather. One of the key tools used in this process is a laser engraving machine, specifically a 10W laser engraver machine. This powerful tool offers a range of benefits for those looking to create high-quality, detailed engravings on Leather Products.

One of the primary advantages of using a 10W laser engraver machine for leather engraving is its precision. The high-powered laser beam can create incredibly detailed designs with sharp edges and fine lines, allowing for intricate patterns and text to be engraved onto the leather surface. This level of precision is difficult to achieve with traditional engraving methods, making the laser engraver machine a valuable tool for leather artisans and designers.

In addition to precision, a 10W laser engraver machine offers speed and efficiency in the engraving process. The laser beam can quickly and accurately engrave designs onto leather, reducing the time and effort required to create custom pieces. This can be especially beneficial for businesses looking to produce large quantities of engraved leather products, as the machine can streamline the production process and increase output.

Another benefit of using a 10W laser engraver machine for leather engraving is its versatility. The machine can be used to engrave a wide range of leather products, including Wallets, belts, bags, and more. It can also engrave on different types of leather, such as Genuine Leather, faux leather, and suede, allowing for a variety of design options. This versatility makes the machine a valuable tool for leather craftsmen and designers looking to create unique and personalized pieces.

Furthermore, a 10W laser engraver machine is easy to use and requires minimal maintenance. The machine is equipped with user-friendly Software that allows for easy design customization and control over the engraving process. Additionally, the machine is durable and reliable, ensuring consistent performance over time. This ease of use and reliability make the machine a practical choice for both experienced professionals and beginners in the field of leather engraving.

In conclusion, a 10W laser engraver machine offers a range of benefits for those looking to create high-quality, detailed engravings on leather products. From precision and speed to versatility and ease of use, this powerful tool is a valuable asset for leather artisans and designers. Whether you are looking to create custom leather products for your business or add personalized touches to your own leather goods, a 10W laser engraver machine can help you achieve professional results with ease.

How to Choose the Right Power Output (80W, 100W, 130W) for a Yongli Tube CO2 Laser Cutting Machine for Wood

When it comes to choosing the right power output for a Yongli Tube CO2 laser cutting machine for wood, there are several factors to consider. The power output of the laser engraving machine will determine the speed and precision of the cutting process, as well as the types of materials that can be cut. In this article, we will discuss the differences between 80W, 100W, and 130W laser engraver machines, and how to choose the right power output for your specific needs.

First and foremost, it is important to understand the power output of a laser engraving machine. The power output is measured in watts, and it determines the strength of the laser beam that is used to cut through materials. A higher power output will result in a faster cutting speed and the ability to cut through thicker materials. However, higher power output machines are also more expensive and may require more maintenance.

An 80W laser engraver machine is a good option for beginners or for those who will be working with thinner materials. This power output is suitable for cutting through materials such as paper, cardboard, and thin wood. An 80W machine is also a good choice for those who will be doing more intricate or detailed work, as it offers a higher level of precision.

On the other hand, a 100W laser engraver machine is a step up in power and is suitable for cutting through thicker materials. This power output is ideal for cutting through materials such as acrylic, leather, and medium-density fiberboard. A 100W machine offers a good balance between speed and precision, making it a versatile option for a wide range of projects.

For those who will be working with even thicker materials or who require a higher level of cutting speed, a 130W laser engraver machine may be the best option. This power output is suitable for cutting through materials such as hardwood, plywood, and thick acrylic. A 130W machine offers the fastest cutting speed and the ability to cut through the thickest materials with ease.

When choosing the right power output for a Yongli Tube CO2 laser cutting machine for wood, it is important to consider the types of materials you will be working with, as well as the level of precision and speed you require. If you are a beginner or will be working with thinner materials, an 80W machine may be sufficient. However, if you require a higher level of cutting speed and the ability to cut through thicker materials, a 100W or 130W machine may be more suitable.

In conclusion, the power output of a laser engraving machine is an important factor to consider when choosing the right machine for your specific needs. By understanding the differences between 80W, 100W, and 130W machines, you can make an informed decision and choose the machine that best suits your requirements. Whether you are a beginner or an experienced professional, there is a Yongli Tube CO2 laser cutting machine for wood that is perfect for your needs.