Table of Contents

Understanding the Properties and Applications of Low Carbon Steel Tube DC-05 AISI 1020

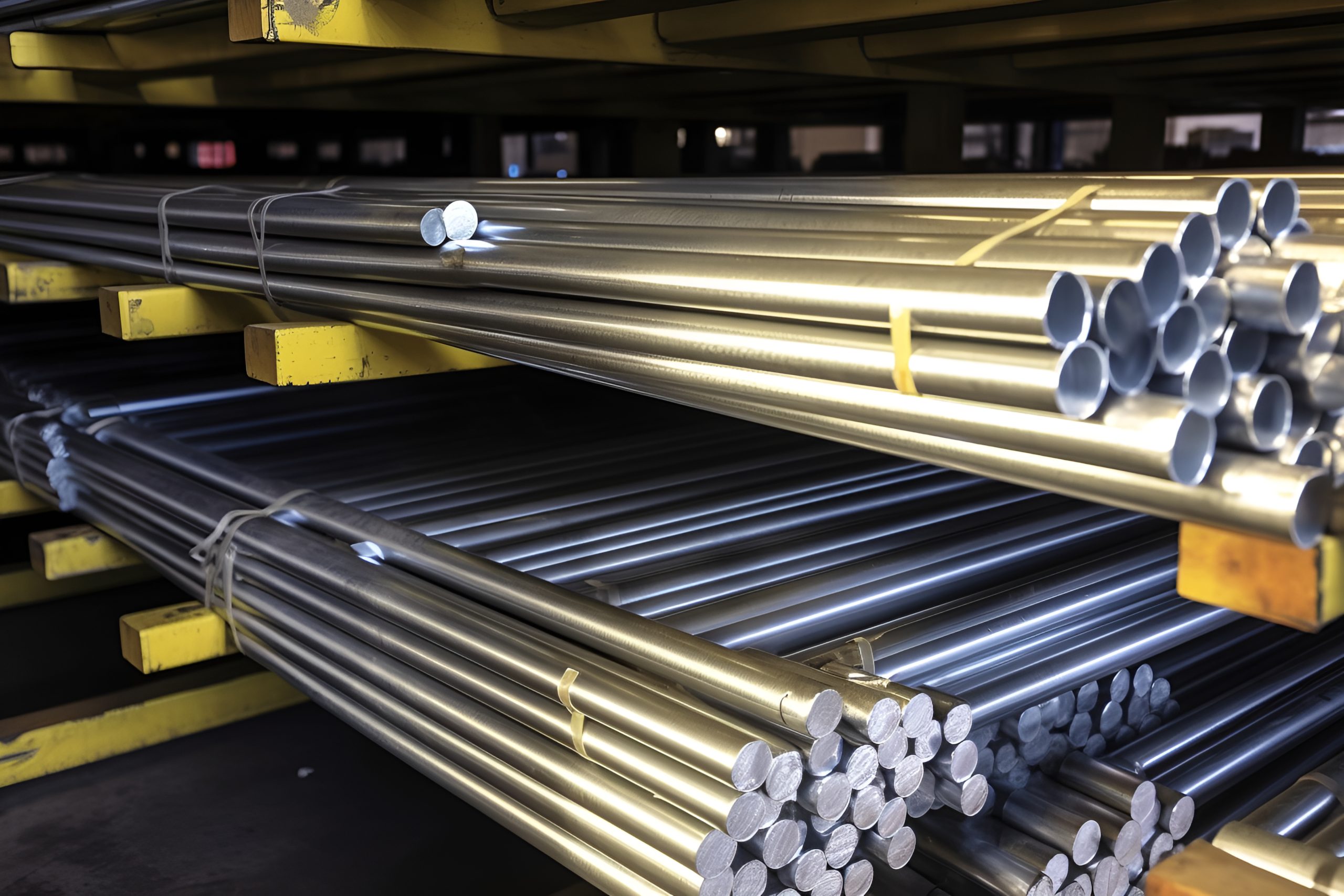

Low carbon steel tubes, particularly those made of DC-05 AISI 1020 seamless carbon steel, represent a vital component in numerous industries due to their exceptional properties and versatile applications. Understanding the properties and applications of these tubes is crucial for various sectors, from manufacturing to construction and beyond.

Low carbon steel, as the name suggests, contains a minimal amount of carbon, typically ranging from 0.05% to 0.30%. This low carbon content makes DC-05 AISI 1020 steel tubes highly malleable and easy to work with, while still offering adequate strength and durability. This unique combination of properties makes them ideal for a wide range of applications.

One of the most notable characteristics of low carbon steel tubes is their excellent weldability. Due to their low carbon content, these tubes can be welded easily without the risk of brittleness or other welding defects. This makes them a preferred choice for manufacturing processes that involve welding, such as fabrication of structural components, piping systems, and automotive parts.

Additionally, low carbon steel tubes exhibit good machinability, allowing for efficient shaping and forming processes. Whether it’s drilling, milling, turning, or any other Machining operation, DC-05 AISI 1020 steel tubes can be readily processed to meet specific dimensional and geometrical requirements. This property is particularly advantageous in industries where precision and customization are paramount, such as aerospace and automotive manufacturing.

Furthermore, the corrosion resistance of low carbon steel tubes can be enhanced through various surface treatments and coatings. While inherently more susceptible to corrosion compared to Stainless Steel or other corrosion-resistant alloys, proper surface protection measures can significantly extend the service life of these tubes, making them suitable for outdoor or corrosive environments.

The applications of DC-05 AISI 1020 seamless carbon steel tubes are diverse and extensive. In the automotive industry, they are commonly used in the construction of chassis, frames, and other structural components due to their high strength-to-weight ratio and formability. Similarly, in the construction sector, these tubes find applications in building frameworks, scaffolding, and architectural structures, thanks to their structural integrity and ease of fabrication.

Moreover, low carbon steel tubes are widely employed in the manufacturing of hydraulic systems, where their excellent weldability and machinability allow for the production of seamless and leak-free tubing assemblies. They are also utilized in the production of Heat Exchangers, Boilers, and other Pressure Vessels, where their combination of strength and ductility is essential for withstanding high temperatures and pressures.

In the realm of consumer goods, DC-05 AISI 1020 steel tubes are increasingly being used in the fabrication of carbon bicycle frames. Their lightweight nature, coupled with their strength and resilience, makes them an ideal choice for constructing durable yet agile bicycle frames that can withstand the rigors of off-road and competitive Cycling.

In conclusion, low carbon steel tubes made of DC-05 AISI 1020 seamless carbon steel offer a multitude of benefits, ranging from excellent weldability and machinability to versatile applications across various industries. Understanding their properties and applications is crucial for leveraging their full potential in manufacturing, construction, automotive, and consumer goods sectors, among others.