Table of Contents

Benefits of Investing in a HP30 3000 Ton Four-Column Hydraulic Press

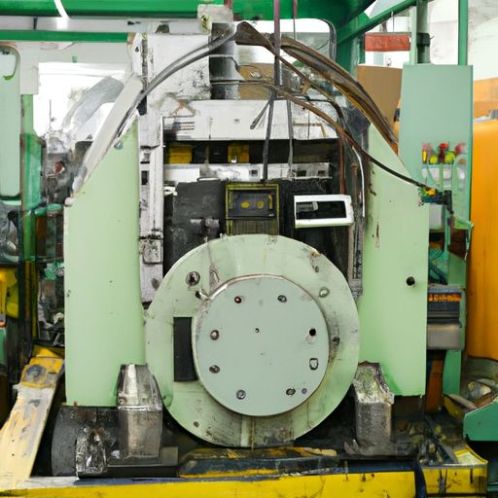

When it comes to Industrial Machinery, investing in high-quality equipment is essential for ensuring efficiency and productivity in manufacturing processes. One such piece of equipment that can greatly benefit a manufacturing operation is the HP30 3000 ton four-column hydraulic press. This powerful machine offers a wide range of benefits that make it a valuable asset for any manufacturing facility.

One of the key benefits of the HP30 hydraulic press is its impressive tonnage capacity. With a maximum tonnage of 3000 tons, this machine is capable of exerting a tremendous amount of force, making it ideal for a wide range of heavy-duty pressing applications. Whether you need to form metal parts, compress materials, or perform other pressing tasks, the HP30 can handle the job with ease.

In addition to its high tonnage capacity, the HP30 hydraulic press also offers exceptional precision and control. The machine is equipped with advanced hydraulic systems that allow for precise control over the pressing process, ensuring that parts are formed accurately and consistently. This level of precision is essential for maintaining quality standards in manufacturing operations and can help reduce waste and rework.

Another benefit of the HP30 hydraulic press is its versatility. This machine is capable of performing a wide range of pressing tasks, thanks to its four-column design and adjustable bed height. Whether you need to press large parts or small components, the HP30 can accommodate a variety of workpieces, making it a versatile solution for a range of manufacturing applications.

In addition to its tonnage capacity, precision, and versatility, the HP30 hydraulic press also offers a number of features that enhance Safety and efficiency in the workplace. The machine is equipped with safety guards and interlocks to protect operators from potential hazards during the pressing process. Additionally, the HP30 is designed for easy maintenance and operation, with user-friendly controls and a durable construction that ensures long-term reliability.

Investing in a HP30 3000 ton four-column hydraulic press can offer a number of benefits for manufacturing operations. From its high tonnage capacity and precision control to its versatility and safety features, this machine is a valuable asset that can help improve efficiency and productivity in the workplace. Whether you need to form metal parts, compress materials, or perform other pressing tasks, the HP30 hydraulic press is a reliable and cost-effective solution that can meet your manufacturing needs.

How to Choose the Right Machine for Sale: HP30 3000 Ton Four-Column Hydraulic Press

When it comes to choosing the right machine for sale, there are several factors to consider. One such machine that is highly sought after in the manufacturing industry is the HP30 3000 ton four-column hydraulic press. This powerful machine is capable of exerting immense pressure to shape and mold various materials, making it an essential tool for many industries.

When it comes to choosing the right machine for sale, there are several factors to consider. One such machine that is highly sought after in the manufacturing industry is the HP30 3000 ton four-column hydraulic press. This powerful machine is capable of exerting immense pressure to shape and mold various materials, making it an essential tool for many industries.

One of the key factors to consider when choosing a hydraulic press is the tonnage capacity. The HP30 boasts an impressive 3000 ton capacity, making it suitable for heavy-duty applications that require high Levels of force. This makes it ideal for tasks such as metal forming, forging, and deep drawing.

In addition to tonnage capacity, it is important to consider the size and dimensions of the machine. The HP30 features a four-column design, which provides stability and precision during operation. This design also allows for a larger working area, making it easier to work with larger materials or multiple pieces at once.

Another important factor to consider when choosing a hydraulic press is the control system. The HP30 is equipped with a state-of-the-art hydraulic system that allows for precise control over the pressure and speed of the machine. This level of control is essential for achieving consistent results and ensuring the safety of the operator.

When it comes to maintenance and upkeep, the HP30 is designed for ease of use. The machine is equipped with a self-lubricating system that reduces the need for frequent maintenance and ensures smooth operation. Additionally, the machine is built with high-quality materials that are designed to withstand the rigors of heavy-duty use.

In terms of safety features, the HP30 is equipped with a range of safety mechanisms to protect both the operator and the machine. These include emergency stop Buttons, safety guards, and overload protection systems. These features help to minimize the risk of accidents and ensure the safe operation of the machine.

Overall, the HP30 3000 ton four-column hydraulic press is a versatile and reliable machine that is well-suited for a wide range of applications. Its high tonnage capacity, precision control system, and robust design make it an ideal choice for manufacturers looking to increase productivity and efficiency.

In conclusion, when choosing a machine for sale, such as the HP30 hydraulic press, it is important to consider factors such as tonnage capacity, size and dimensions, control system, maintenance requirements, and safety features. By carefully evaluating these factors, manufacturers can ensure they choose the right machine for their specific needs and requirements.

Maintenance Tips for Keeping Your KN Hydraulic Press in Top Condition

When it comes to industrial machinery, proper maintenance is key to ensuring optimal performance and longevity. This is especially true for Hydraulic Presses, such as the KN HP30 3000 ton four-column hydraulic press. Regular maintenance not only helps prevent costly breakdowns and downtime but also ensures the safety of operators and the quality of the products being produced.

One of the most important maintenance tasks for a hydraulic press is keeping the hydraulic system in good working order. This includes checking and replacing hydraulic fluid, inspecting hoses and fittings for leaks or damage, and monitoring pressure levels. Regularly scheduled hydraulic system maintenance can help prevent issues such as overheating, loss of pressure, and component failure.

In addition to the hydraulic system, it is also important to regularly inspect and maintain other components of the hydraulic press, such as the electrical system, mechanical components, and safety features. This includes checking for loose or worn parts, lubricating moving components, and testing safety features such as emergency stops and interlocks.

Another important aspect of maintaining a hydraulic press is keeping it clean and free of debris. Dust, dirt, and other contaminants can build up on the machine over time, leading to decreased performance and potential damage. Regularly cleaning the machine, including the hydraulic system, electrical components, and mechanical parts, can help prevent these issues and keep the press running smoothly.

In addition to regular maintenance tasks, it is also important to address any issues or concerns as soon as they arise. Ignoring small problems can Lead to larger issues Down the road, potentially causing costly repairs or even machine failure. If you notice any unusual noises, vibrations, leaks, or other signs of trouble, it is important to investigate and address the issue promptly.

When it comes to maintaining a hydraulic press, it is also important to follow the manufacturer’s recommendations and guidelines. This includes using the correct type and amount of hydraulic fluid, following recommended maintenance schedules, and using proper techniques for operating the machine. By following these guidelines, you can help ensure the longevity and performance of your hydraulic press.

In conclusion, proper maintenance is essential for keeping your KN HP30 3000 ton four-column hydraulic press in top condition. By regularly inspecting and maintaining the hydraulic system, other components, and cleanliness of the machine, you can help prevent issues, ensure safety, and prolong the life of the press. Addressing any issues promptly and following manufacturer recommendations are also key aspects of maintaining a hydraulic press. By taking these steps, you can help ensure that your hydraulic press continues to operate efficiently and effectively for years to come.