Table of Contents

Benefits of Metal Enclosure Fabrication Services

Metal enclosure fabrication services offer a wide range of benefits for businesses looking to create custom parts for their products. From steel welding to deep drawing parts, these services provide the expertise and precision needed to produce high-quality components that meet specific requirements. One of the key advantages of using metal enclosure fabrication services is the ability to create parts that are tailored to the exact specifications of a project. This level of customization ensures that the final product will fit perfectly and function as intended.

Steel welding is a common process used in metal enclosure fabrication services to join metal pieces together. This technique is essential for creating strong and durable components that can withstand the rigors of everyday use. By using steel welding, fabricators can create seamless connections between different parts, ensuring that the final product is structurally sound and reliable.

Deep drawing parts is another important aspect of metal enclosure fabrication services. This process involves forming metal sheets into complex shapes and designs using a series of dies and punches. Deep drawing allows fabricators to create intricate components with precise dimensions and tight tolerances. This level of precision is crucial for ensuring that the final product meets the exact requirements of a project.

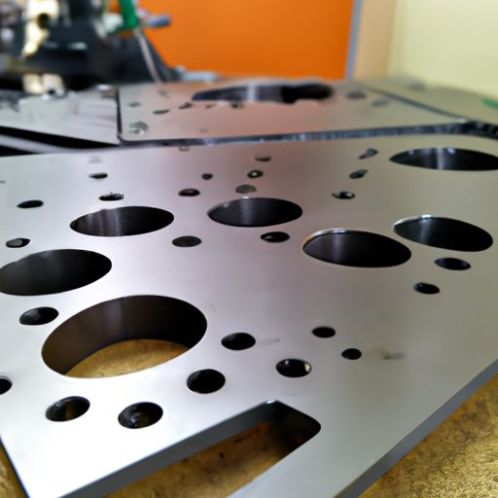

Position drilling is a key step in the fabrication process that involves creating holes in metal components to accommodate Fasteners or Other Hardware. This process requires careful planning and precise execution to ensure that the holes are positioned correctly and aligned with other features of the part. By using position drilling, fabricators can create parts that are easy to assemble and disassemble, making maintenance and repairs more efficient.

Machining is another important service offered by metal enclosure fabrication companies. This process involves using specialized tools and equipment to shape and finish metal components to the desired specifications. Machining allows fabricators to create parts with smooth surfaces, tight tolerances, and complex geometries. This level of precision is essential for ensuring that the final product functions properly and looks professional.

Custom CNC (Computer Numerical Control) machining is a cutting-edge technology that allows fabricators to create highly detailed and complex parts with incredible accuracy. By using custom CNC machining, fabricators can produce parts with intricate designs and tight tolerances that would be impossible to achieve using traditional methods. This level of precision is essential for creating parts that meet the exact requirements of a project and perform reliably in real-world applications.

Custom CNC (Computer Numerical Control) machining is a cutting-edge technology that allows fabricators to create highly detailed and complex parts with incredible accuracy. By using custom CNC machining, fabricators can produce parts with intricate designs and tight tolerances that would be impossible to achieve using traditional methods. This level of precision is essential for creating parts that meet the exact requirements of a project and perform reliably in real-world applications.

In conclusion, metal enclosure fabrication services offer a wide range of benefits for businesses looking to create custom parts for their products. From steel welding to deep drawing parts, these services provide the expertise and precision needed to produce high-quality components that meet specific requirements. By utilizing these services, businesses can create parts that are tailored to their exact specifications, ensuring that the final product is structurally sound, reliable, and visually appealing. Whether you need position drilling, machining, or custom CNC services, metal enclosure fabrication companies have the expertise and technology to bring your project to life.