Table of Contents

Benefits of Using Industrial Granule Hopper Injection Dryer for Plastic Pellets

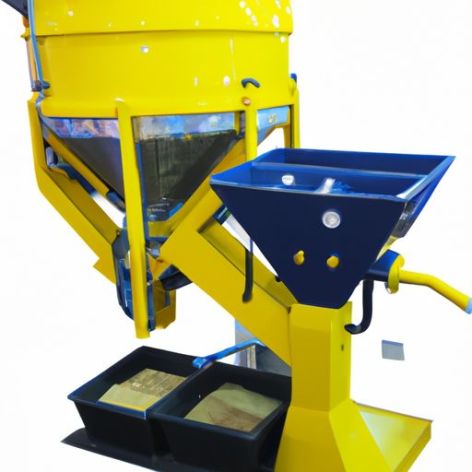

Plastic pellets are a common material used in various industries for manufacturing products such as Containers, packaging, and automotive parts. However, before these pellets can be used in the production process, they need to be dried to remove any moisture that may have been absorbed during storage or transportation. This is where industrial granule hopper injection dryers come into play.

These dryers are specifically designed to efficiently and effectively dry plastic pellets, ensuring that they are free from moisture and ready for use in the manufacturing process. One of the key benefits of using an industrial granule hopper injection dryer is the hot air recovery system. This system allows for the Recycling of hot air, reducing energy consumption and operating costs.

By recycling hot air, industrial granule hopper injection dryers are able to maintain a consistent and controlled drying Environment, ensuring that the plastic pellets are dried evenly and thoroughly. This not only improves the quality of the dried pellets but also reduces the risk of defects in the final products.

In addition to the hot air recovery system, industrial granule hopper injection dryers also offer a high level of automation and control. These dryers are equipped with advanced Sensors and controls that monitor and adjust the drying process in real-time, ensuring optimal drying conditions are maintained at all times.

This level of automation not only improves the efficiency of the drying process but also reduces the risk of human error, resulting in more consistent and reliable drying results. Furthermore, industrial granule hopper injection dryers are designed to be user-friendly, with intuitive interfaces that make operation and maintenance simple and straightforward.

Another benefit of using an industrial granule hopper injection dryer is the ability to customize the drying process to meet specific requirements. These dryers can be easily adjusted to accommodate different types of plastic pellets, drying temperatures, and drying times, allowing for flexibility and versatility in the manufacturing process.

This customization capability ensures that the drying process is tailored to the specific needs of the plastic pellets being dried, resulting in optimal drying results and improved product quality. Additionally, industrial granule hopper injection dryers are designed to be durable and reliable, with high-quality components that are built to last.

This durability ensures that the dryer can withstand the rigors of continuous use in an industrial setting, providing long-term performance and reliability. Overall, the benefits of using an industrial granule hopper injection dryer for plastic pellets are clear. From the hot air recovery system to the advanced automation and control features, these dryers offer a range of advantages that can improve the efficiency, quality, and consistency of the drying process.

Whether you are a small-scale manufacturer or a large industrial operation, investing in an industrial granule hopper injection dryer can help you achieve better drying results and ultimately improve the quality of your products. With their advanced features and customizable capabilities, these dryers are a valuable asset for any business looking to optimize their plastic pellet drying process.

How Hot Air Recovery Systems Can Improve Efficiency in Plastic Pellet Drying Operations

Plastic pellet drying is a crucial step in the manufacturing process of Plastic Products. Properly dried pellets ensure the quality and consistency of the final product. One of the key components in a pellet drying system is the hot air recovery system. This system plays a vital role in improving efficiency and reducing energy consumption in plastic pellet drying operations.

Hot air recovery systems work by capturing and reusing the heat generated during the drying process. This heat is then recycled and used to preheat the incoming air, reducing the amount of energy needed to heat the air to the desired temperature. By utilizing this heat recovery process, manufacturers can significantly reduce their energy costs and improve the overall efficiency of their drying operations.

In addition to reducing energy consumption, hot air recovery systems also help to maintain a consistent drying temperature. This is essential for ensuring that the pellets are dried evenly and thoroughly, resulting in a high-quality final product. By recycling the heat generated during the drying process, manufacturers can achieve more precise control over the drying temperature, leading to improved product quality and consistency.

Another benefit of hot air recovery systems is their ability to reduce the environmental impact of plastic pellet drying operations. By reusing heat that would otherwise be wasted, manufacturers can lower their carbon footprint and contribute to a more sustainable manufacturing process. This is especially important in today’s world, where environmental concerns are at the forefront of many industries.

Hot air recovery systems are available in a variety of configurations to suit different drying requirements. Some systems are designed to work with specific types of dryers, while others can be integrated into existing drying systems. Regardless of the configuration, hot air recovery systems offer a cost-effective solution for improving efficiency and reducing energy consumption in plastic pellet drying operations.

When considering the purchase of a hot air recovery system, it is important to evaluate the specific needs of your drying operation. Factors such as the size of the drying operation, the type of pellets being dried, and the desired drying temperature should all be taken into account when selecting a hot air recovery system. Consulting with a knowledgeable supplier or manufacturer can help ensure that you choose the right system for your specific requirements.

In conclusion, hot air recovery systems play a crucial role in improving efficiency and reducing energy consumption in plastic pellet drying operations. By capturing and reusing heat generated during the drying process, these systems help to maintain a consistent drying temperature, reduce energy costs, and lower the environmental impact of plastic manufacturing. Investing in a hot air recovery system can Lead to significant cost savings and improved product quality, making it a valuable addition to any plastic pellet drying operation.