Table of Contents

Benefits of Using Pick and Place Machines for Desktop PCB Board LED High Speed Assembly

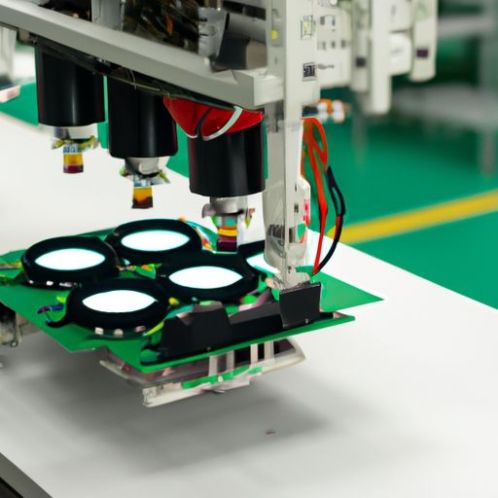

Pick and place machines have revolutionized the way electronic components are assembled onto printed circuit Boards (PCBs). These machines offer a high level of precision and efficiency, making them an essential tool for manufacturers looking to streamline their production processes. In this article, we will explore the benefits of using pick and place machines for desktop PCB board LED high-speed assembly.

One of the key advantages of pick and place machines is their ability to automate the assembly process. These machines are equipped with multiple heads that can pick up components from a feeder and accurately place them onto the PCB. This automation reduces the need for manual labor, saving time and increasing productivity. Additionally, pick and place machines can work at a much faster pace than human operators, allowing for higher throughput and shorter Lead times.

Another benefit of using pick and place machines is the level of precision they offer. These machines are capable of placing components with micron-level accuracy, ensuring that each component is placed in the correct position on the PCB. This level of precision is essential for ensuring the quality and reliability of the finished product. By using pick and place machines, manufacturers can avoid costly errors and rework, leading to higher yields and lower production costs.

Pick and place machines also offer flexibility in terms of component placement. These machines can handle a wide range of component sizes and shapes, making them suitable for a variety of PCB assembly applications. Whether you are assembling small LED Bulbs or larger electronic components, pick and place machines can accommodate your needs. Additionally, these machines can be easily reconfigured to accommodate changes in component sizes or assembly requirements, providing manufacturers with the flexibility they need to adapt to changing market demands.

In addition to their precision and flexibility, pick and place machines also offer consistency in component placement. These machines can repeat the same assembly process over and over again with the same level of accuracy, ensuring that each PCB is assembled to the same high standard. This consistency is essential for maintaining product quality and reliability, especially in industries where precision is critical. By using pick and place machines, manufacturers can ensure that each PCB meets the required specifications and standards.

Furthermore, pick and place machines can help manufacturers reduce their environmental impact. By automating the assembly process, these machines can minimize waste and reduce energy consumption. Additionally, the high level of precision offered by pick and place machines can help manufacturers minimize the use of materials and resources, further reducing their environmental footprint. By using pick and place machines, manufacturers can improve their sustainability practices and contribute to a greener future.

In conclusion, pick and place machines offer a wide range of benefits for manufacturers looking to streamline their production processes. From automation and precision to flexibility and consistency, these machines can help manufacturers improve their efficiency, quality, and sustainability. If you are looking to enhance your desktop PCB board LED high-speed assembly process, consider investing in a pick and place machine to take your production to the next level.

How to Optimize Efficiency in 6-Head LED Bulb Assembly with Fully Automatic Factory Manufacturer PCB SMT Technology

In the world of electronics manufacturing, efficiency is key. With the rise of LED technology, the demand for LED bulbs has increased significantly. To meet this demand, manufacturers are constantly looking for ways to optimize their assembly processes. One way to achieve this is through the use of fully automatic factory manufacturer PCB SMT technology.

One such technology that has gained popularity in recent years is the pick and place desktop PCB board LED high-speed 6-head LED bulb assembly machine. This machine is designed to streamline the assembly process by automatically picking up components and placing them on the PCB board with precision and speed. By utilizing this technology, manufacturers can significantly increase their production output while maintaining high Levels of quality.

One of the key benefits of using a 6-head LED bulb assembly machine is its ability to handle multiple components simultaneously. This means that the machine can pick up and place up to six components at a time, significantly reducing the time it takes to assemble a single PCB board. This not only increases production efficiency but also allows manufacturers to meet tight deadlines and customer demands.

Furthermore, the high-speed capabilities of the machine ensure that components are placed quickly and accurately, reducing the risk of errors and defects. This is crucial in LED bulb assembly, where precision is paramount to ensure the functionality and longevity of the final product. By using a 6-head LED bulb assembly machine, manufacturers can minimize the risk of costly rework and ensure that each PCB board meets the required specifications.

Another advantage of using fully automatic factory manufacturer PCB SMT technology is the ability to optimize the assembly process. By programming the machine to follow a specific assembly sequence, manufacturers can ensure that components are placed in the correct order and orientation. This not only improves the efficiency of the assembly process but also reduces the likelihood of errors and rework.

Additionally, the machine can be equipped with advanced features such as vision systems and automatic component feeders, further enhancing its capabilities. Vision systems can be used to inspect components before placement, ensuring that only high-quality components are used in the assembly process. Automatic component feeders can also be used to replenish components as needed, reducing downtime and increasing overall efficiency.

In conclusion, fully automatic factory manufacturer PCB SMT technology, such as the pick and place desktop PCB board LED high-speed 6-head LED bulb assembly machine, offers manufacturers a cost-effective and efficient solution for LED bulb assembly. By utilizing this technology, manufacturers can increase production output, improve assembly quality, and meet customer demands with ease. With its advanced features and capabilities, the 6-head LED bulb assembly machine is a valuable asset for any electronics manufacturer looking to optimize their assembly process.