Table of Contents

Benefits of Using Stainless Steel Water Pumps for Silicone-Based Coolant Liquids

Stainless steel water pumps are a popular choice for handling silicone-based coolant liquids due to their durability, corrosion resistance, and ability to maintain the purity of the liquid being pumped. These pumps are specifically designed to handle the unique properties of silicone-based coolant liquids, making them an ideal choice for a wide range of industrial applications.

One of the key benefits of using stainless steel water pumps for silicone-based coolant liquids is their ability to withstand the harsh conditions often found in industrial environments. Stainless steel is known for its high strength and corrosion resistance, making it an ideal material for pumps that will be used to handle aggressive Chemicals and liquids. This means that stainless steel water pumps are less likely to corrode or degrade over time, ensuring a longer lifespan and lower maintenance costs.

In addition to their durability, stainless steel water pumps are also highly efficient at transferring silicone-based coolant liquids. The smooth surface of stainless steel helps to reduce friction and improve the flow of the liquid, resulting in higher efficiency and lower energy consumption. This can Lead to cost savings for businesses that rely on silicone-based coolant liquids for their operations.

Another advantage of using stainless steel water pumps for silicone-based coolant liquids is their ability to maintain the purity of the liquid being pumped. Stainless steel is a non-reactive material, meaning that it will not leach any harmful substances into the liquid being pumped. This is particularly important when working with sensitive materials or in industries where purity is critical, such as the pharmaceutical or Food And Beverage industries.

Furthermore, stainless steel water pumps are easy to clean and sanitize, making them a hygienic choice for handling silicone-based coolant liquids. The smooth surface of stainless steel prevents bacteria and other contaminants from adhering to the pump, reducing the risk of contamination and ensuring the purity of the liquid being pumped. This is essential for industries where cleanliness and sanitation are of utmost importance.

One of the key features of stainless steel water pumps is their speed control capabilities. Many stainless steel water pumps come equipped with variable speed drives, allowing users to adjust the flow rate of the pump to meet their specific needs. This level of control is essential for industries that require precise dosing or flow rates, such as in chemical processing or pharmaceutical manufacturing.

In conclusion, stainless steel water pumps offer a range of benefits for handling silicone-based coolant liquids. Their durability, efficiency, and ability to maintain the purity of the liquid make them an ideal choice for a wide range of industrial applications. With their speed control capabilities and ease of cleaning, stainless steel water pumps are a reliable and hygienic option for businesses looking to optimize their operations.

How Speed Control in Magnetic Drive Gear Pumps Enhances Dosing Efficiency

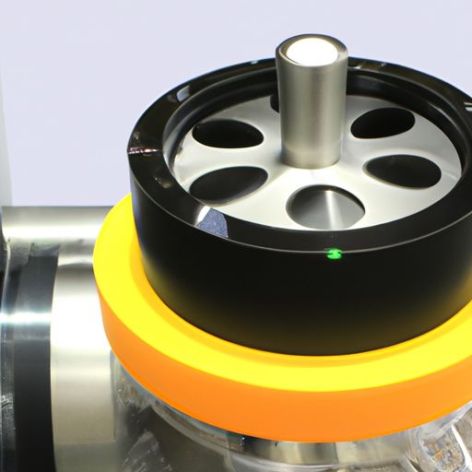

Magnetic drive gear pumps are a crucial component in various industries where precise dosing of liquids is required. These pumps are known for their reliability, efficiency, and ability to handle a wide range of fluids, including silicone-based coolant liquids. One key feature that sets magnetic drive gear pumps apart from other types of pumps is their speed control capabilities.

Speed control in magnetic drive gear pumps plays a significant role in enhancing dosing efficiency. By allowing operators to adjust the speed at which the pump operates, they can fine-tune the flow rate of the liquid being dosed. This level of control is essential when dealing with sensitive or expensive fluids, as even small variations in flow rate can have a significant impact on the final product.

One of the main benefits of speed control in magnetic drive gear pumps is the ability to achieve precise dosing accuracy. By adjusting the speed of the pump, operators can ensure that the correct amount of liquid is dispensed at the right time. This level of precision is crucial in industries such as pharmaceuticals, where even the slightest deviation from the prescribed dosage can have serious consequences.

Speed control also allows for greater flexibility in dosing applications. Different fluids may require different flow rates to achieve the desired result, and being able to adjust the speed of the pump makes it easier to accommodate these variations. This flexibility is particularly useful in industries where multiple liquids are being dosed simultaneously or where dosing requirements change frequently.

In addition to enhancing dosing accuracy and flexibility, speed control in magnetic drive gear pumps can also help improve overall efficiency. By optimizing the flow rate of the pump, operators can minimize waste and reduce the risk of over or under-dosing. This not only saves money but also ensures that the final product meets the required specifications.

Another advantage of speed control in magnetic drive gear pumps is the ability to extend the lifespan of the pump itself. By operating the pump at lower speeds when possible, operators can reduce wear and tear on the internal components, leading to fewer breakdowns and maintenance issues. This can result in cost savings over time and help ensure that production runs smoothly without unexpected interruptions.

Overall, speed control in magnetic drive gear pumps is a valuable feature that can greatly enhance dosing efficiency in a wide range of industries. By providing operators with the ability to adjust the flow rate of the pump, these pumps offer greater precision, flexibility, and efficiency in dosing applications. Whether dosing silicone-based coolant liquids or other fluids, magnetic drive gear pumps with speed control capabilities are an essential tool for achieving optimal results.