Table of Contents

Strategies for Reducing Machine Textile Steam in Chenille Spinning Finishing Machine to Minimize Fabric Shrinkage

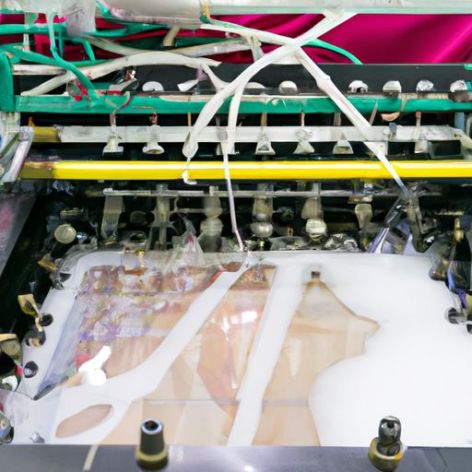

Textile steam plays a crucial role in the finishing process of chenille Spinning Machines. However, excessive steam can Lead to fabric shrinkage, which is a common issue faced by manufacturers. In order to minimize fabric shrinkage, it is important to implement strategies to reduce machine textile steam in chenille spinning finishing machines.

One effective strategy is to carefully monitor and control the steam pressure and temperature settings on the machine. By ensuring that the steam pressure is not too high and the temperature is within the recommended range, manufacturers can prevent excessive steam from causing fabric shrinkage. Regular maintenance and calibration of the machine’s steam system can also help to ensure that it is operating efficiently and effectively.

Another strategy is to optimize the steam distribution system within the machine. By ensuring that steam is evenly distributed throughout the fabric during the finishing process, manufacturers can minimize the risk of localized shrinkage. This can be achieved by adjusting the positioning of steam nozzles and ensuring that they are clean and free from blockages.

In addition, manufacturers can consider using alternative finishing techniques that require less steam. For example, some chenille spinning machines offer the option of using hot air instead of steam for the finishing process. By exploring these alternative techniques, manufacturers can reduce their reliance on steam and minimize the risk of fabric shrinkage.

It is also important to consider the type of fabric being processed when determining the appropriate steam settings for the machine. Different fabrics have different shrinkage properties, so it is important to adjust the steam settings accordingly. Manufacturers should conduct thorough testing and experimentation to determine the optimal steam settings for each type of fabric to minimize shrinkage.

Furthermore, implementing quality control measures throughout the production process can help to identify and address any issues related to fabric shrinkage. By conducting regular inspections and testing of finished products, manufacturers can quickly identify any instances of shrinkage and take corrective action. This can help to prevent shrinkage from occurring in future production runs.

Overall, reducing machine textile steam in chenille spinning finishing machines is essential for minimizing fabric shrinkage. By carefully monitoring and controlling steam settings, optimizing steam distribution, exploring alternative finishing techniques, adjusting settings based on fabric type, and implementing quality control measures, manufacturers can effectively reduce the risk of fabric shrinkage and produce high-quality finished products. By implementing these strategies, manufacturers can ensure that their chenille spinning machines operate efficiently and effectively, while minimizing the risk of fabric shrinkage.

Overall, reducing machine textile steam in chenille spinning finishing machines is essential for minimizing fabric shrinkage. By carefully monitoring and controlling steam settings, optimizing steam distribution, exploring alternative finishing techniques, adjusting settings based on fabric type, and implementing quality control measures, manufacturers can effectively reduce the risk of fabric shrinkage and produce high-quality finished products. By implementing these strategies, manufacturers can ensure that their chenille spinning machines operate efficiently and effectively, while minimizing the risk of fabric shrinkage.