Table of Contents

Benefits of Using Water Tank Copper Wire Machine with Annealer Drawing Machine JCJX-14B Full Immersion

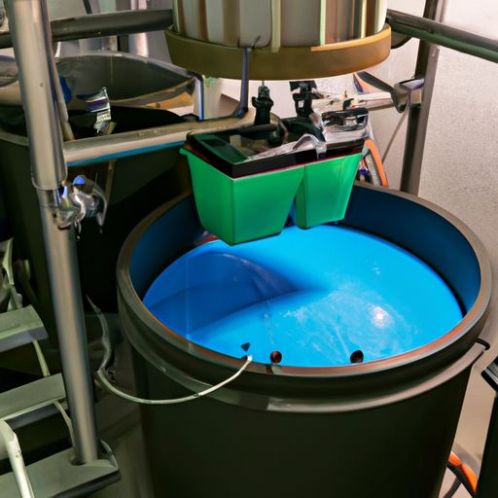

Water Tank Copper Wire machine with annealer Drawing Machine JCJX-14B Full Immersion is a cutting-edge technology that offers numerous benefits to industries that rely on copper wire production. This advanced machine combines the processes of drawing and annealing in a single unit, streamlining the production process and improving efficiency.

One of the key benefits of using the Water Tank Copper Wire machine with annealer Drawing Machine JCJX-14B Full Immersion is its ability to produce high-quality copper wire with consistent properties. The annealing process helps to soften the wire, making it more malleable and easier to work with. This results in a finished product that is free from defects and has uniform mechanical properties.

In addition to improving the quality of the copper wire, the Water Tank Copper Wire machine with annealer Drawing Machine JCJX-14B Full Immersion also offers significant cost savings for manufacturers. By combining the drawing and annealing processes into a single machine, companies can reduce the number of machines needed for production, saving on both equipment costs and floor space. This streamlined production process also reduces the amount of labor required, further lowering production costs.

Another advantage of using the Water Tank Copper Wire machine with annealer Drawing Machine JCJX-14B Full Immersion is its energy efficiency. The machine is designed to operate at optimal efficiency, using minimal energy to produce high-quality copper wire. This not only reduces operating costs for manufacturers but also helps to minimize the environmental impact of production.

Furthermore, the Water Tank Copper Wire machine with annealer Drawing Machine JCJX-14B Full Immersion is highly versatile and can be used to produce a wide range of copper wire sizes and types. This flexibility allows manufacturers to easily adapt to changing market demands and produce custom wire products to meet specific customer requirements.

The Water Tank Copper Wire machine with annealer Drawing Machine JCJX-14B Full Immersion is also designed for ease of use and maintenance. The machine is equipped with user-friendly controls and interfaces, making it simple for operators to set up and monitor the production process. Additionally, the machine is built with high-quality components that are designed to withstand the rigors of continuous operation, reducing the need for frequent maintenance and repairs.

Overall, the Water Tank Copper Wire machine with annealer Drawing Machine JCJX-14B Full Immersion offers numerous benefits to industries that rely on copper wire production. From improved quality and cost savings to energy efficiency and versatility, this advanced machine is a valuable asset for manufacturers looking to enhance their production processes and stay competitive in the market.