Table of Contents

Benefits of Using Welded HDG Gi Pre Galvanized Steel Pipe in Construction Projects

Welded HDG Gi Pre Galvanized Steel Pipe is a popular choice for construction projects due to its durability, strength, and corrosion resistance. This type of steel pipe is made by coating the steel with a layer of Zinc, which helps to protect it from rust and corrosion. The zinc coating also gives the steel a shiny, attractive finish that is ideal for use in a variety of construction applications.

One of the key benefits of using Welded HDG Gi Pre Galvanized Steel Pipe in construction projects is its strength. The zinc coating helps to protect the steel from damage, making it ideal for use in structures that need to withstand heavy loads or harsh environmental conditions. This type of steel pipe is also highly resistant to corrosion, which means that it will last for many years without needing to be replaced.

Another advantage of using Welded HDG Gi Pre Galvanized Steel Pipe is its versatility. This type of steel pipe can be used in a wide range of construction applications, including building frames, scaffolding, fencing, and more. Its shiny finish also makes it a popular choice for decorative applications, such as handrails and Gates.

In addition to its strength and versatility, Welded HDG Gi Pre Galvanized Steel Pipe is also easy to work with. This type of steel pipe can be welded, cut, and shaped to fit a variety of construction needs. Its smooth surface also makes it easy to paint or coat with other materials, allowing for endless customization options.

One of the main reasons why Welded HDG Gi Pre Galvanized Steel Pipe is so popular in construction projects is its cost-effectiveness. This type of steel pipe is relatively inexpensive compared to other materials, making it a budget-friendly option for builders and contractors. Its long lifespan and low maintenance requirements also help to save money in the long run, as it will not need to be replaced or repaired as often as other materials.

Overall, Welded HDG Gi Pre Galvanized Steel Pipe is a durable, versatile, and cost-effective option for construction projects. Its strength, corrosion resistance, and ease of use make it an ideal choice for a wide range of applications. Whether you are building a new structure or renovating an existing one, Welded HDG Gi Pre Galvanized Steel Pipe is a reliable and efficient choice that will help you get the job done right.

Seamless Carbon Steel Pipe vs. Hot DIP Galvanised Steel Tube: A Comparison for Construction Applications

When it comes to construction applications, choosing the right type of steel pipe is crucial for ensuring the durability and longevity of the structure. Two popular options in the construction industry are seamless carbon Steel Pipes and hot-dip galvanized steel tubes. Both have their own unique properties and advantages, making them suitable for different types of construction projects.

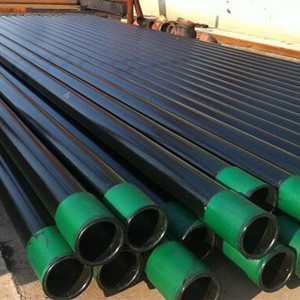

Seamless carbon steel pipes are made from solid, round steel Billets that are heated and pierced to create a hollow tube. This manufacturing process results in a pipe that is strong, durable, and resistant to corrosion. Seamless carbon steel pipes are known for their high tensile strength and ability to withstand high pressure and temperature conditions, making them ideal for applications where reliability and performance are key.

On the other hand, hot-dip galvanized steel tubes are steel pipes that have been coated with a layer of zinc through a process called hot-dip galvanizing. This coating provides an additional layer of protection against corrosion, making hot-dip galvanized steel tubes ideal for outdoor and high-moisture environments. The zinc coating also helps to extend the lifespan of the steel tube, making it a cost-effective option for long-term construction projects.

One of the main differences between seamless carbon steel pipes and hot-dip galvanized steel tubes is their corrosion resistance. While seamless carbon steel pipes are naturally resistant to corrosion due to their solid construction, hot-dip galvanized steel tubes offer an added layer of protection against rust and corrosion. This makes hot-dip galvanized steel tubes a popular choice for outdoor construction projects, such as fences, handrails, and water pipelines.

In terms of cost, seamless carbon steel pipes are generally more expensive than hot-dip galvanized steel tubes. This is due to the complex manufacturing process involved in producing seamless carbon steel pipes, as well as the higher quality of the material used. However, the long-term benefits of seamless carbon steel pipes, such as their durability and reliability, often outweigh the initial cost.

When it comes to installation, both seamless carbon steel pipes and hot-dip galvanized steel tubes are relatively easy to work with. Seamless carbon steel pipes can be welded together using various welding techniques, while hot-dip galvanized steel tubes can be connected using threaded fittings or couplings. Both options offer flexibility in terms of installation, making them suitable for a wide range of construction applications.

In conclusion, both seamless carbon steel pipes and hot-dip galvanized steel tubes have their own unique properties and advantages that make them suitable for construction applications. Seamless carbon steel pipes are known for their high tensile strength and durability, while hot-dip galvanized steel tubes offer added protection against corrosion. The choice between the two will ultimately depend on the specific requirements of the construction project, as well as budget constraints and environmental factors. Ultimately, both options are reliable and cost-effective solutions for construction applications.