Table of Contents

Casing Pipe vs. Drill Pipe: Understanding the Key Differences

Casing pipe and drill pipe are two essential components in the oil and gas industry, each serving a distinct purpose in the drilling process. While they may appear similar at first glance, there are key differences between the two that are important to understand in order to ensure the success of drilling operations.

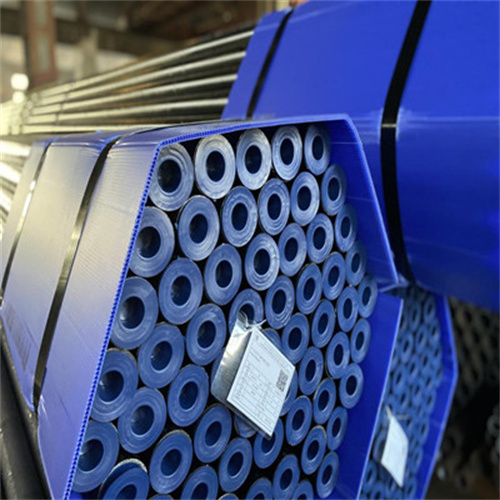

Casing pipe is used to line the walls of a drilled well to prevent the hole from collapsing and to isolate different geological formations. It is typically made of steel and comes in various sizes and grades to accommodate different drilling conditions. Casing pipe is installed as the well is being drilled, with each section of pipe being connected and lowered into the hole as the drilling progresses.

Drill pipe, on the other hand, is used to transmit drilling fluid and torque from the drilling rig to the drill bit at the bottom of the hole. It is also made of steel and is designed to withstand high Levels of stress and torque during the drilling process. Drill pipe is connected to the drilling rig at the surface and extends Down into the wellbore, allowing for the rotation and advancement of the drill bit.

One of the key differences between casing pipe and drill pipe is their respective functions in the drilling process. Casing pipe is primarily used to protect the wellbore and provide structural support, while drill pipe is used to transmit power and drilling fluid to the drill bit. This distinction is important because each component plays a crucial role in the overall success of drilling operations.

Another important difference between casing pipe and drill pipe is their design and construction. Casing pipe is typically thicker and heavier than drill pipe, as it needs to withstand the weight of the overlying rock formations and provide support for the wellbore. Drill pipe, on the other hand, is designed to be more flexible and lightweight to allow for easy handling and movement during drilling operations.

In addition to their functions and design, casing pipe and drill pipe also differ in terms of their connections and threading. Casing pipe is typically connected using threaded connections that are designed to provide a tight seal and prevent leaks, while drill pipe is connected using a tool joint that allows for quick and easy assembly and disassembly.

Despite these differences, casing pipe and drill pipe are both essential components in the drilling process and work together to ensure the success of drilling operations. By understanding the key differences between the two, drilling operators can make informed decisions about the selection and use of casing pipe and drill pipe in their drilling projects.

In conclusion, while casing pipe and drill pipe may appear similar at first glance, they serve distinct purposes in the drilling process and have key differences in terms of their functions, design, and connections. By understanding these differences, drilling operators can ensure the success of their drilling operations and maximize the efficiency and effectiveness of their drilling projects.