Table of Contents

Benefits of Using Wire Mesh in Industrial Applications

Wire mesh is a versatile material that has a wide range of applications in various industries. One of the key benefits of using wire mesh in industrial applications is its durability and strength. Wire mesh is typically made from materials such as Copper, brass, or Stainless Steel, which are known for their high tensile strength and resistance to corrosion. This makes wire mesh an ideal choice for applications where the material will be subjected to harsh conditions or heavy loads.

In addition to its strength, wire mesh also offers excellent flexibility and versatility. Wire mesh can be easily shaped and molded to fit a wide range of applications, making it a popular choice for industries such as construction, Agriculture, and manufacturing. Whether you need a fine mesh for filtering or a sturdy mesh for fencing, wire mesh can be customized to meet your specific requirements.

Another key benefit of using wire mesh in industrial applications is its ability to provide effective shielding and protection. Copper Wire Mesh, for example, is commonly used for electromagnetic shielding in electronic devices and equipment. The fine mesh structure of copper wire provides a barrier that blocks electromagnetic interference, ensuring the proper functioning of sensitive electronic components.

Brass wire mesh is another popular choice for industrial applications due to its excellent corrosion resistance and aesthetic appeal. Brass wire mesh is often used in architectural applications such as decorative screens and facades, where its unique golden hue adds a touch of elegance to the design.

In addition to its durability and shielding properties, wire mesh also offers excellent airflow and visibility. Wire mesh with a larger mesh size allows for better ventilation and airflow, making it an ideal choice for applications such as air filtration and ventilation systems. The open structure of wire mesh also provides good visibility, making it suitable for applications where visibility is important, such as Security fencing or animal enclosures.

One of the key advantages of using wire mesh in industrial applications is its cost-effectiveness. Wire mesh is a relatively inexpensive material compared to other options such as solid metal sheets or plastic panels. This makes wire mesh an attractive choice for businesses looking to reduce costs without compromising on quality or performance.

In conclusion, wire mesh offers a wide range of benefits for industrial applications, including durability, strength, flexibility, shielding, and cost-effectiveness. Whether you need a fine mesh for filtering or a sturdy mesh for fencing, wire mesh can be customized to meet your specific requirements. With its versatility and reliability, wire mesh is a valuable material that can enhance the performance and efficiency of various industrial processes.

How to Choose the Right Type of Wire Mesh for Your Project

Wire mesh is a versatile material that is commonly used in a wide range of applications, from industrial to residential. It is made by weaving or welding together strands of metal wire to create a grid-like pattern. The size of the openings in the mesh, known as the mesh size, can vary widely depending on the intended use of the material. One important factor to consider when choosing wire mesh is the mesh size, which is typically measured in microns or mesh count.

When selecting wire mesh for a project, it is important to consider the specific requirements of the application. For example, if the mesh will be used for filtering or straining purposes, a finer mesh size may be required to ensure that only particles of a certain size can pass through. On the other hand, if the mesh will be used for structural support or fencing, a coarser mesh size may be more appropriate.

One common type of wire mesh is 200 mesh micron wire, which is a fine mesh that is often used for filtering or sieving applications. This type of mesh is made from copper wire, which is known for its durability and resistance to corrosion. Copper wire Cloth is also commonly used for shielding applications, as it can effectively block electromagnetic interference.

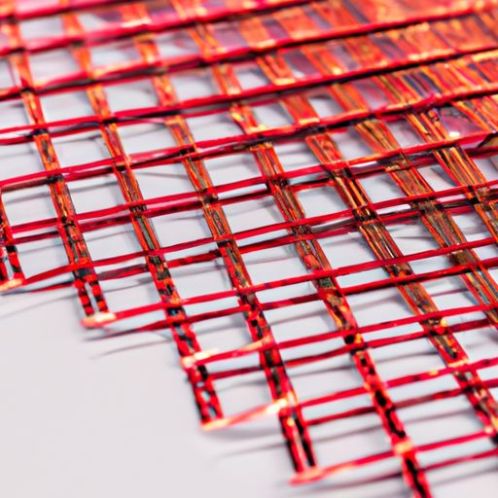

Another popular type of wire mesh is red copper wire, which is made from a high-purity copper alloy that is known for its excellent conductivity and thermal properties. Red copper wire is often used in electrical applications, such as grounding and bonding, as well as in decorative applications, such as architectural mesh.

Brass copper wire mesh is another common type of wire mesh that is made from a combination of copper and Zinc. This type of mesh is known for its strength and corrosion resistance, making it ideal for outdoor applications. Brass copper wire mesh is often used in fencing, screening, and decorative applications.

When choosing the right type of wire mesh for your project, it is important to consider not only the mesh size and material, but also the weave pattern. Wire mesh can be woven in a variety of patterns, including plain weave, twill weave, and Dutch weave, each of which has its own unique characteristics and advantages.

In conclusion, wire mesh is a versatile material that can be used in a wide range of applications. When choosing the right type of wire mesh for your project, it is important to consider factors such as mesh size, material, and weave pattern. By carefully considering these factors, you can ensure that you select the wire mesh that best meets the requirements of your application.