Table of Contents

فوائد استخدام كبسولات الجيلاتين الصلبة في المكملات الغذائية

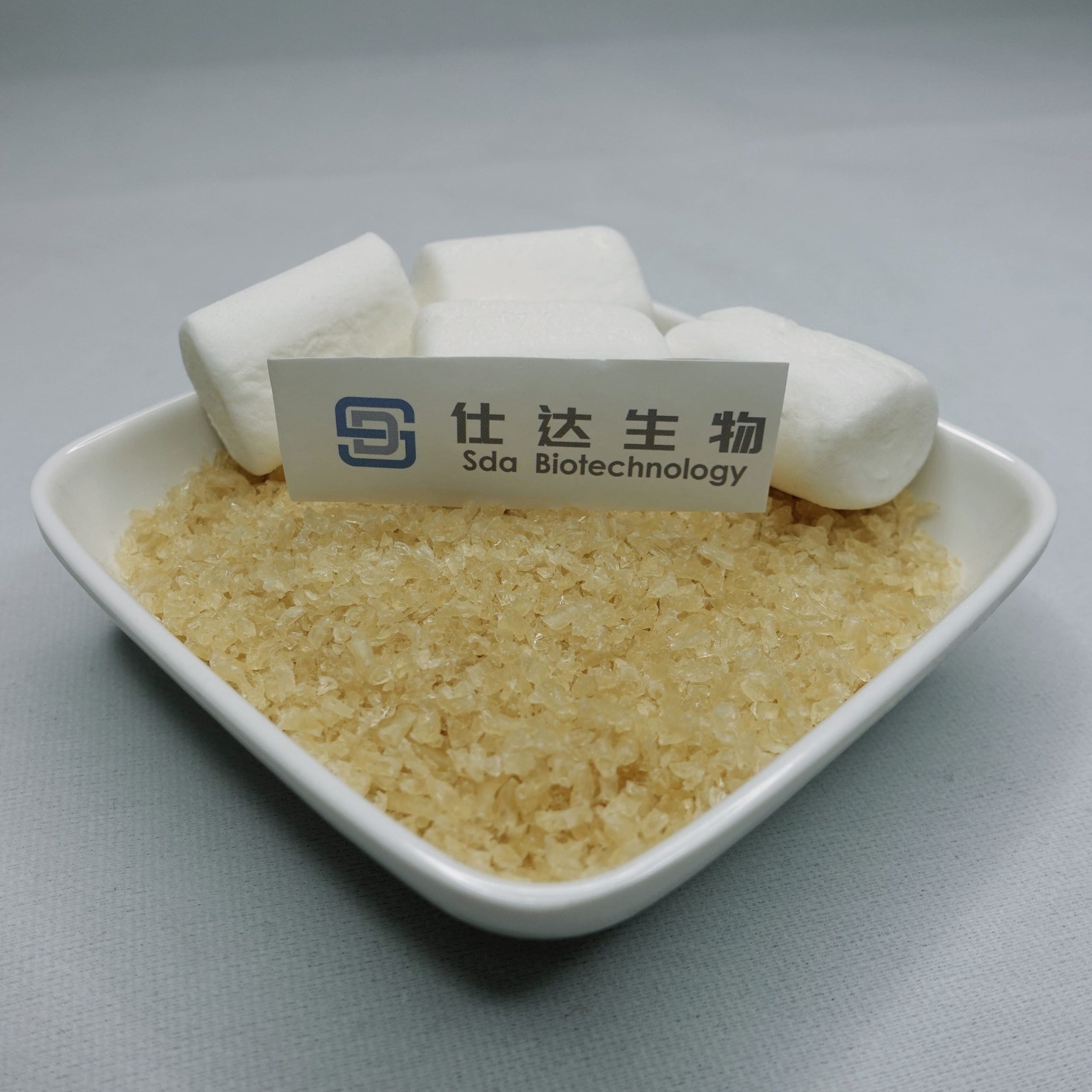

اسم المنتج:

| الجيلاتين الصالح للأكل/مسحوق الجيلاتين/الجيلاتين | نوع الاستخدام: |

| وظائف مثل الجيل، والرغوة، والثبات، والسماكة، والالتصاق | مدة الصلاحية: |

| 2 سنة | المحتوى: |

| تركيبة الكولاجين، الماء، الأحماض الأمينية | رقم سجل المستخلصات الكيميائية: |

| التطبيقات: | 9000-70-8 |

| المضافات الغذائية، كبسولات المنتجات الصحية | رقم الموديل: |

| 120 بلوم-300 بلوم | حجم الجسيمات: |

| 8-60 شبكة | الحد الأدنى لكمية الطلب: |

| 500 كيلوجرام | رمز النظام المنسق: |

| الحزمة: | 3503001000 |

| 25 كجم حقيبة التعبئة | تعليمات الاستخدام: |

| يذوب في الماء حسب نسبة الاستخدام | نظرة من وراء الكواليس إلى عملية إنتاج الجيلاتين في أحد المصانع |

في الختام، يعد إنتاج كبسولات الجيلاتين الصلبة ذات الكبسولات الصلبة عملية معقدة تتطلب اهتمامًا دقيقًا بالتفاصيل ومراقبة صارمة للجودة. بدءًا من اختيار المواد الخام وحتى الفحص النهائي للمنتج النهائي، تعد كل خطوة من خطوات عملية الإنتاج أمرًا بالغ الأهمية لضمان تلبية كبسولات الجيلاتين لأعلى معايير الجودة والسلامة. من خلال إلقاء نظرة من وراء الكواليس على عملية إنتاج الجيلاتين في المصنع، يمكننا الحصول على تقدير أكبر للمهارة والخبرة التي تدخل في إنتاج هذا المكون متعدد الاستخدامات.

A Behind-the-Scenes Look at the Production Process of Gelatin in a Factory

Gelatin is a versatile ingredient that is used in a wide range of products, from pharmaceuticals to food and cosmetics. One of the most common forms of gelatin is hard capsule gelatin microcapsules, which are used to encapsulate health ingredients. In this article, we will take a behind-the-scenes look at the production process of gelatin in a factory.

The production of gelatin starts with the selection of high-quality raw materials. The main source of gelatin is animal Collagen, which is extracted from the skin, bones, and connective tissues of animals such as cows and pigs. The raw materials are carefully inspected to ensure that they meet the strict quality standards required for gelatin production.

Once the raw materials have been selected, they are cleaned and processed to remove any impurities. This process involves washing, soaking, and boiling the raw materials to extract the collagen. The collagen is then treated with Enzymes to break it Down into smaller molecules, which are then filtered and purified to remove any remaining impurities.

The purified collagen is then mixed with water and heated to form a gel. This gel is then poured into molds and allowed to cool and set. Once the gel has set, it is cut into small pieces and dried to remove any excess moisture. The dried gel pieces are then ground into a fine powder, which is the final product known as gelatin.

The gelatin powder is then used to produce hard capsule gelatin microcapsules. These microcapsules are made by mixing the gelatin powder with the health ingredients that are to be encapsulated. The mixture is then poured into molds and allowed to set, forming small capsules that contain the health ingredients.

The production of hard capsule gelatin microcapsules requires precision and attention to detail. The molds must be carefully filled to ensure that each capsule contains the correct amount of gelatin and health ingredients. The capsules must also be allowed to set for the right amount of time to ensure that they are properly formed and do not break or leak.

Once the capsules have set, they are removed from the molds and inspected for quality. Any capsules that do not meet the required standards are discarded, while the rest are packaged and prepared for distribution.

In conclusion, the production of hard capsule gelatin microcapsules is a complex process that requires careful attention to detail and strict quality control. From the selection of raw materials to the final inspection of the finished product, every step of the production process is crucial to ensuring that the gelatin capsules meet the highest standards of quality and Safety. By taking a behind-the-scenes look at the production process of gelatin in a factory, we can gain a greater appreciation for the skill and expertise that goes into producing this versatile ingredient.