目录

在保健品中使用硬胶囊明胶微胶囊的好处

硬胶囊明胶微胶囊因其众多优点而在保健品行业中越来越受欢迎。这些微胶囊由明胶制成,明胶是一种从动物骨骼和皮肤中发现的胶原蛋白中提取的蛋白质。明胶以其在活性成分周围形成保护屏障的能力而闻名,从而实现控制释放和提高生物利用度。

在保健补充剂中使用硬胶囊明胶微胶囊的主要好处之一是它们能够保护敏感成分免遭降解。许多维生素、矿物质和其他促进健康的化合物对光、热和水分敏感,这会降低其功效。通过将这些成分封装在明胶微胶囊中,制造商可以确保它们在食用前保持稳定和有效。

除了保护敏感成分外,硬胶囊明胶微胶囊还可以提高生物利用度。明胶壳有助于保护活性成分免受胃部恶劣酸性环境的影响,使它们能够通过小肠,在那里可以更有效地吸收。这意味着消费者可以从补充剂中获得更多益处,而无需服用更大剂量。

使用硬胶囊明胶微胶囊的另一个优点是其多功能性。这些微胶囊可以填充多种成分,包括维生素、矿物质、益生菌和草药提取物。这使得制造商能够创建定制配方,以满足目标受众的特定需求。无论是促进整体健康的多种维生素还是针对特定病症的专门补充剂,明胶微胶囊都提供了方便有效的输送系统。

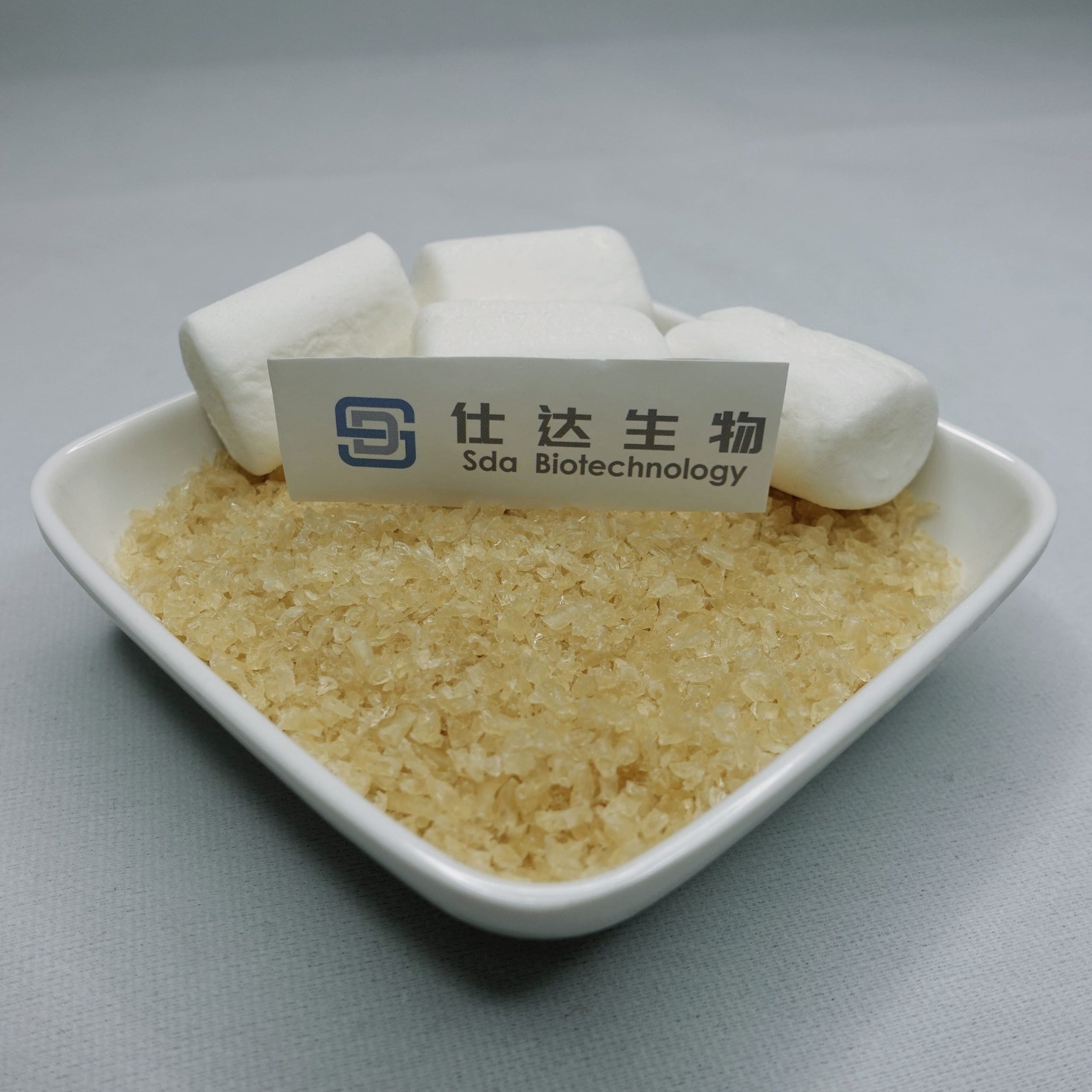

| 产品名称: | Edible gelatin/Gelatin Powder/Gelatine |

| Use type: | Functions such as gelation, foaming, stability, thickening, adhesion |

| Shelf Life: | 2 Years |

| Content: | Collagen, water, Amino Acid composition |

| CAS No.: | 9000-70-8 |

| Applications: | Food Additives, Health product capsules |

| Model Number: | 120 Bloom-300 Bloom |

| Particle Size: | 8-60 Mesh |

| Minimum order quantity: | 500 kilograms |

| HS CODE: | 3503001000 |

| Package: | 25KG packing bag |

| Instruction for use: | Dissolve in water according to the use proportion |

Furthermore, hard capsule gelatin microcapsules are easy to swallow and digest, making them ideal for individuals who have difficulty taking traditional tablets or capsules. The smooth gelatin shell glides easily Down the throat and breaks down quickly in the stomach, releasing the active ingredients for absorption. This can be particularly beneficial for children, the elderly, and anyone with swallowing issues.

In addition to their benefits for consumers, hard capsule gelatin microcapsules also offer advantages for manufacturers. These microcapsules are easy to produce in large quantities, making them a cost-effective option for supplement companies. The gelatin shell can be customized in terms of size, shape, and color, allowing for branding and marketing opportunities. Furthermore, gelatin is a natural and sustainable ingredient, making it an attractive choice for companies looking to appeal to environmentally conscious consumers.

Overall, the use of hard capsule gelatin microcapsules in health supplements offers a range of benefits for both consumers and manufacturers. From improved stability and bioavailability to versatility and ease of use, these microcapsules provide a convenient and effective delivery system for a wide range of health-promoting ingredients. As the demand for high-quality supplements continues to grow, hard capsule gelatin microcapsules are likely to play an increasingly important role in the industry.

A Behind-the-Scenes Look at the Production Process of Gelatin in a Factory

Gelatin is a versatile ingredient that is used in a wide range of products, from pharmaceuticals to food and cosmetics. One of the most common forms of gelatin is hard capsule gelatin microcapsules, which are used to encapsulate health ingredients. In this article, we will take a behind-the-scenes look at the production process of gelatin in a factory.

The production of gelatin starts with the selection of high-quality raw materials. The main source of gelatin is animal collagen, which is extracted from the skin, bones, and connective tissues of animals such as cows and pigs. The raw materials are carefully inspected to ensure that they meet the strict quality standards required for gelatin production.

Once the raw materials have been selected, they are cleaned and processed to remove any impurities. This process involves washing, soaking, and boiling the raw materials to extract the collagen. The collagen is then treated with Enzymes to break it down into smaller molecules, which are then filtered and purified to remove any remaining impurities.

The purified collagen is then mixed with water and heated to form a gel. This gel is then poured into molds and allowed to cool and set. Once the gel has set, it is cut into small pieces and dried to remove any excess moisture. The dried gel pieces are then ground into a fine powder, which is the final product known as gelatin.

The gelatin powder is then used to produce hard capsule gelatin microcapsules. These microcapsules are made by mixing the gelatin powder with the health ingredients that are to be encapsulated. The mixture is then poured into molds and allowed to set, forming small capsules that contain the health ingredients.

The production of hard capsule gelatin microcapsules requires precision and attention to detail. The molds must be carefully filled to ensure that each capsule contains the correct amount of gelatin and health ingredients. The capsules must also be allowed to set for the right amount of time to ensure that they are properly formed and do not break or leak.

Once the capsules have set, they are removed from the molds and inspected for quality. Any capsules that do not meet the required standards are discarded, while the rest are packaged and prepared for distribution.

In conclusion, the production of hard capsule gelatin microcapsules is a complex process that requires careful attention to detail and strict quality control. From the selection of raw materials to the final inspection of the finished product, every step of the production process is crucial to ensuring that the gelatin capsules meet the highest standards of quality and Safety. By taking a behind-the-scenes look at the production process of gelatin in a factory, we can gain a greater appreciation for the skill and expertise that goes into producing this versatile ingredient.